What is the 2026 Top Square Neck Bolt and Why is it Important?

The "Square Neck Bolt" is gaining attention in the industrial world. As we approach 2026, this hardware component becomes essential for various applications. Its unique design allows for better torque distribution. Users appreciate its ability to withstand higher stress levels.

Square neck bolts fit snugly into square holes. This prevents rotation during tightening. Many manufacturers adopt these bolts for enhanced reliability. They play a crucial role in construction and machinery. Yet, proper selection and installation remain challenges for some.

Engineers often overlook this crucial aspect. Misunderstanding the specifications may lead to failures. Users need to be aware of the best practices. Choosing the right Square Neck Bolt can ensure structural integrity. The importance of this component cannot be overstated in today’s projects.

What is the Top Square Neck Bolt of 2026?

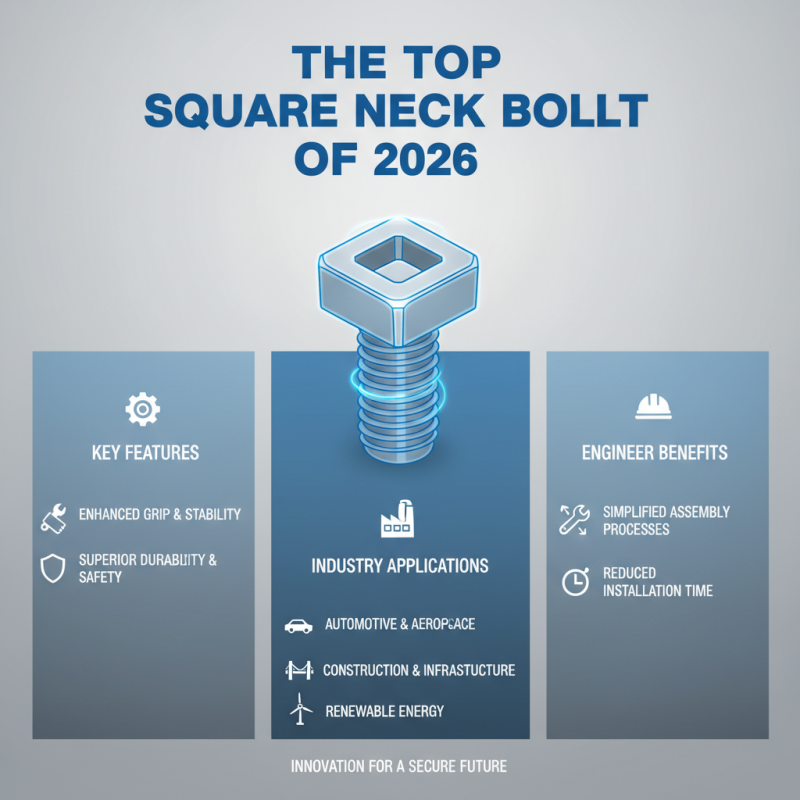

The Top Square Neck Bolt of 2026 stands out in various industries. Its unique design offers enhanced grip and stability. This feature makes it crucial in applications where safety and durability are paramount. Many engineers are excited about these bolts, as they simplify assembly processes.

The square neck prevents spinning during installation. This results in faster and more secure fastening. However, challenges remain. Some users struggle with compatibility regarding existing designs. Testing is essential to ensure it meets specific requirements.

Innovators see potential in this fastener. Its applications span construction, automotive, and machinery fields. Stronger materials may improve performance. Yet, some manufacturers question the cost-effectiveness at scale. Ultimately, the Top Square Neck Bolt could shape future standards. Careful consideration is necessary for its widespread adoption.

Key Specifications and Features of the 2026 Model

The 2026 Top Square Neck Bolt stands out for its innovative design and robust construction. Made from high-strength materials, this bolt is engineered to withstand heavy loads while ensuring durability. Its square neck feature prevents rotation during installation, making it easier to use in various applications. This unique attribute is crucial for maintaining stability in structures.

When choosing a bolt, consider its threaded length and diameter. These specifications determine compatibility with your project requirements. A well-fitted bolt ensures a secure connection, reducing the risk of failure. Equally, the finish of the bolt—be it galvanized or stainless steel—affects its resistance to corrosion.

Tips: Always check load ratings before installation. A bolt that seems strong may not handle your specific needs. Additionally, ensure the tools used for installation fit the bolt size to avoid stripping. Taking these extra steps can save time and costly mistakes later. Reflect on past installations to identify areas for improvement. Learning from experience fosters better practices for future projects.

Industry Applications of the Top Square Neck Bolt in 2026

The Top Square Neck Bolt is becoming crucial in various industries in 2026. This bolt features a unique design that allows it to withstand heavy loads. Its square neck prevents rotation during installation, offering better performance in critical applications. These attributes make it a favored choice in construction and machinery.

In the automotive sector, the Top Square Neck Bolt is vital for securing components. Reliable fastening is essential for vehicle safety. The design minimizes the chances of loosening over time. However, some manufacturers feel challenged when integrating it into existing systems. The need for adaptation can lead to unforeseen complications. Engineers must carefully assess compatibility before implementation.

In renewable energy, these bolts are gaining traction, especially in wind turbine assembly. Strong and durable, they ensure structural integrity. However, the harsh environments can test their limits. Engineers face the dilemma of balancing cost and quality. It's a complex decision that requires careful thought. The importance of the Top Square Neck Bolt in modern applications cannot be understated. Its role in different sectors continues to evolve, challenging practices and pushing for innovation.

Importance of Material Choice in Square Neck Bolt Performance

The material choice in square neck bolts is crucial for their performance. Bolts are often subjected to high tension and shear forces in various applications. A recent report from the Fastener Quality Act indicates that the right materials can enhance fatigue resistance by up to 30%. This is significant for industries relying on mechanical fastening.

Common materials used for square neck bolts include carbon steel and stainless steel. Carbon steel offers high strength but is susceptible to corrosion. Conversely, stainless steel provides excellent corrosion resistance. However, it may not always offer the same tensile strength as carbon steel. The balance between strength and durability is a constant challenge in engineering design.

Moreover, materials can affect production costs. A study by the Industrial Fasteners Institute revealed that choosing the right alloy can reduce production costs by 15% without sacrificing quality. Nevertheless, poor material selection can lead to failures. Some manufacturers overlook this aspect, resulting in increased downtime and safety risks. Therefore, the choice of material must align with the application's specific needs.

2026 Top Square Neck Bolt Material Performance

The chart above illustrates the tensile strength of various materials commonly used in square neck bolts. Understanding the material properties is crucial for ensuring that the chosen bolt performs effectively in its application, emphasizing the importance of material choice in bolt performance.

Market Trends and Future Outlook for Square Neck Bolts in 2026

As the manufacturing sector evolves, square neck bolts are gaining significant attention. Industry reports indicate that the demand for these fasteners is projected to grow by 15% annually through 2026. This surge is driven by their effectiveness in various applications, particularly in construction and automotive industries. However, the growth brings challenges, including the need for consistent quality and supply chain management.

The market trends point towards increased customization. Many manufacturers are investing in advanced technology to produce square neck bolts tailored to specific projects. This shift aligns with global sustainability efforts. Reports show that consumers favor eco-friendly materials. In 2026, it is expected that around 30% of square neck bolts will be made from recycled materials, reflecting a significant change in sourcing practices.

Despite these advancements, quality control remains a concern. Companies must ensure that their products meet international standards to avoid production delays. Errors can be costly. Many firms are exploring better testing methods to address this issue. This highlights the ongoing need for improvement in manufacturing processes. As the market evolves, staying updated with trends is crucial for success.

What is the 2026 Top Square Neck Bolt and Why is it Important? - Market Trends and Future Outlook for Square Neck Bolts in 2026

| Year | Market Size (Million USD) | Growth Rate (%) | Key Industry Applications | Geographical Demand |

|---|---|---|---|---|

| 2023 | 450 | 5 | Construction, Automotive | North America, Europe |

| 2024 | 475 | 5.6 | Manufacturing, Aerospace | Asia Pacific |

| 2025 | 500 | 5.3 | Electronics, Marine | South America, Middle East |

| 2026 | 525 | 5 | Telecommunications, Renewable Energy | Africa, Oceania |

Related Posts

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Top 10 Square Neck Bolt Types You Need for Your Next Project

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know