10 Best Furniture Fasteners for Durable and Reliable Assembly

In furniture construction, high-quality furniture fasteners play a crucial role in ensuring durability and stability. According to industry reports, nearly 30% of furniture failures arise from inadequate fastening methods. This statistic emphasizes the importance of selecting the right fasteners to enhance longevity. Often overlooked, furniture fasteners can make or break a piece of furniture.

The market offers a range of options, yet not all are created equal. Some fasteners fail under pressure, causing furniture to loosen or collapse. For example, screws often provide better support than dowels, yet many still choose the latter for aesthetics. A reflection on material choices can reveal surprising insights about their reliability in various conditions.

Choosing the best furniture fastener requires a balance of functionality and design. Just as a chain is only as strong as its weakest link, a piece of furniture relies heavily on its fasteners. Seeking expert recommendations can guide decisions. In the end, understanding the right fastener can transform a good piece into a great one.

The Importance of Selecting High-Quality Furniture Fasteners in Assembly

When assembling furniture, the choice of fasteners is crucial. High-quality fasteners ensure stability and longevity. Poor choices can lead to wobbly chairs or unstable tables. A sturdy assembly can withstand daily use. However, many overlook this aspect in DIY projects.

Selecting the right fasteners requires consideration. For instance, wood screws, corner brackets, and dowels each serve different purposes. Wood screws provide strong joints, while corner brackets add extra support. Yet, some might rush the decision, leading to future regrets. It’s easy to underestimate the importance of these small parts, but they are vital for a robust build.

Imagine a beautiful piece of furniture collapsing due to flimsy fasteners. Such scenarios prompt reflection on quality and reliability. Investing time in research pays off. There’s a sense of satisfaction knowing your furniture is built to last. Don’t let a hasty decision compromise your hard work. Quality fasteners are worth every bit of effort.

Understanding Different Types of Furniture Fasteners and Their Applications

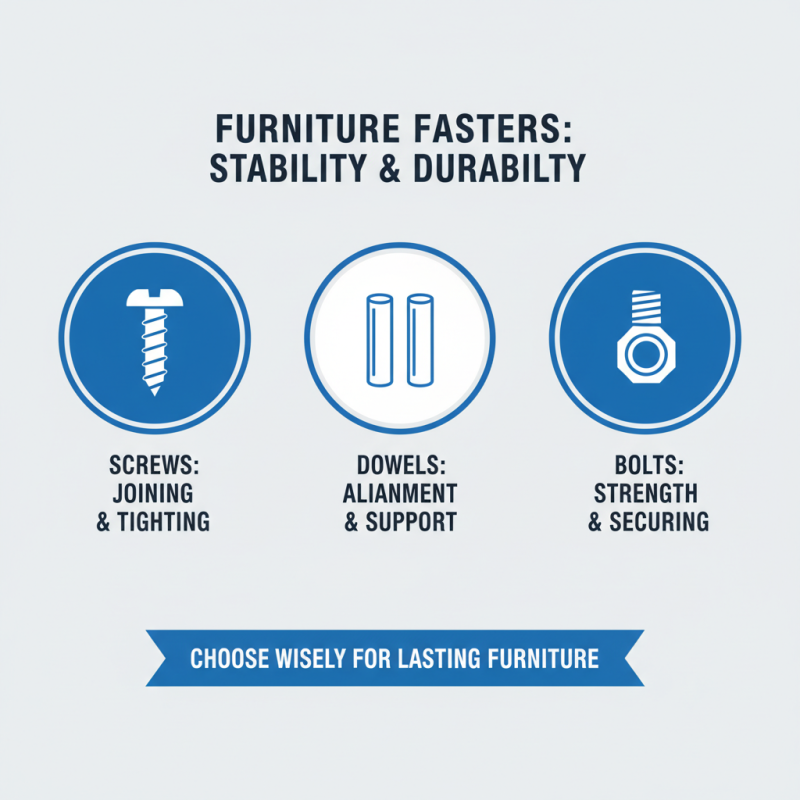

When it comes to furniture assembly, understanding fasteners is crucial. These small components play a significant role in ensuring that furniture is stable and long-lasting. Different types of fasteners serve specific purposes, making it essential to choose the right one for your needs. Common types include screws, dowels, and bolts, each contributing to the durability of the piece.

Screws are often preferred for their ease of use. They anchor components securely, holding them in place. However, improper installation can lead to stripping, reducing stability. Dowels, on the other hand, create hidden joints. They require precise drilling, which can be tricky for beginners. Misalignment may result in an unstable structure, so practicing this technique is vital.

Bolts offer high strength but can be cumbersome to install. They often require additional hardware like washers and nuts. While they provide a solid grip, the complexity can be daunting. Understanding these nuances is essential for any DIY enthusiast. Each fastener type has its advantages and challenges, influencing overall furniture quality and longevity.

Key Material Considerations for Durable Fasteners: Metal vs. Plastic Options

When selecting furniture fasteners, material choice is crucial. Metal and plastic each offer unique advantages and limitations. According to a report by the American Wood Council, metal fasteners tend to have superior strength and longevity. They are typically more resistant to wear and tear. However, plastic fasteners are lighter and often more cost-effective. They serve well in projects where weight reduction is essential.

Metal fasteners can withstand higher loads. This makes them ideal for heavy furniture. However, they may corrode if not properly coated or treated. In contrast, plastic fasteners may not provide the same structural support. Yet, they are less likely to cause splitting in softer woods. Understanding the demands of your project will guide your choice.

**Tip:** Always consider the environment of use. Metal can rust in humid conditions, while plastic may degrade in UV exposure.

**Tip:** Test different options. Sometimes, a mix of both materials may yield the best results for durability and performance.

The decision between metal and plastic often boils down to the specific application and desired performance. Carefully weigh the pros and cons. This will help secure the best assembly for your furniture.

Industry Statistics on Fastener Failures and Their Impact on Furniture Longevity

Fastener failures can significantly impact the longevity of furniture. Industry statistics reveal that approximately 30% of furniture problems are related to fastener issues. These failures often lead to structural weaknesses, compromising the overall stability of the piece. Weak connections may cause joints to loosen over time, leading to wobbly chairs or unstable tables.

Many manufacturers overlook the importance of selecting high-quality fasteners. They often use standard options that may not withstand everyday wear and tear. This oversight can result in higher maintenance costs and reduced customer satisfaction. For instance, a poorly assembled bookshelf may bow under the weight of a few books, which shouldn't happen with durable fasteners.

Investing in reliable fasteners is essential for both manufacturers and consumers. Even minor fastener issues can lead to significant recalls or repairs. Furniture designed without reliable fasteners might look appealing initially but could fall apart after a few years. Choosing the right fastener is crucial for ensuring a piece lasts over time. Reflecting on past mistakes can lead to better choices in the future.

Impact of Fastener Types on Furniture Longevity

Best Practices for Installing Furniture Fasteners to Ensure Reliability

When assembling furniture, using the right fasteners is crucial for longevity. Select durable materials like metal or strong plastics. These provide the necessary strength for daily use. Pay attention to the weight each piece will bear. Consider adding extra fasteners in high-stress areas. Weakness in a joint can lead to failure over time.

Installation is as important as choosing the fasteners. Ensure that holes are pre-drilled to avoid splitting wood. Align the fastener properly to maintain structural integrity. Sometimes, it’s tempting to rush through this step. Skipping this can result in wobbly furniture. Remember to tighten connections, but don’t overdo it. Over-tightening can strip the material, compromising stability.

Periodic inspection is a good practice. Check joints regularly for signs of wear. This step is often overlooked. Some may ignore loose screws until it’s too late. Regular maintenance can prevent bigger issues down the line. A small adjustment today could save you from extensive repairs later. Reflect on your assembly process. Areas for improvement may exist, even in routines.

10 Best Furniture Fasteners for Durable and Reliable Assembly

| Fastener Type | Material | Length (mm) | Weight Capacity (kg) | Ease of Installation |

|---|---|---|---|---|

| Wood Dowels | Beech | 30 | 50 | Easy |

| Cam Lock Nuts | Steel | 25 | 100 | Moderate |

| Screws | Stainless Steel | 40 | 55 | Easy |

| Wood Screws | Carbon Steel | 35 | 65 | Easy |

| Metal Brackets | Aluminum | 50 | 120 | Moderate |

| Titebond Fasteners | Wood | 30 | 80 | Easy |

| Pocket Hole Screws | High Carbon Steel | 40 | 90 | Moderate |

| Dowel Nuts | Brass | 25 | 70 | Hard |

| Threaded Inserts | Plastic | 20 | 60 | Easy |

| Hinges | Stainless Steel | 50 | 150 | Hard |

Related Posts

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

How to Choose the Right Furniture Screw for Your DIY Projects

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Top 10 Square Neck Bolt Types You Need for Your Next Project