Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

When it comes to construction and engineering projects, the choice of fasteners significantly influences the overall strength and durability of structures. Among the various types of fasteners, High Tensile Carriage Bolts have gained recognition for their superior mechanical properties, making them a preferred option in both industrial and commercial applications. According to the Mechanical Fasteners Association, high tensile bolts typically provide up to 30% greater tensile strength compared to standard bolts, ensuring they can withstand higher loads and resist deformation under stress.

In addition to their strength, High Tensile Carriage Bolts are designed to resist corrosion and wear, leading to enhanced longevity and reliability in various environmental conditions. Industry reports suggest that using high tensile fasteners can reduce maintenance costs and improve the safety of structural assemblies, which is crucial in sectors like construction, automotive, and manufacturing. As projects become more demanding, the necessity for robust fastening solutions has never been more critical, highlighting the importance of selecting the right High Tensile Carriage Bolt for your needs.

Understanding High Tensile Carriage Bolts: Definition and Uses

High tensile carriage bolts are a specific category of fasteners that stand out due to their enhanced strength and durability. These bolts feature a specially designed square neck that prevents rotation during installation, making them versatile for various applications. Typically crafted from high-strength steels and often coated to resist corrosion, high tensile carriage bolts are ideal for structural connections in both wood and metal frameworks. Their ability to withstand significant tensile loads makes them essential in construction, automotive, and industrial sectors where safety and reliability are paramount.

The applications of high tensile carriage bolts extend beyond mere fastening. They can be found in assembling outdoor furniture, securing fences, and connecting structural beams in buildings. Their design allows for easy installation with a wrench, providing a secure connection without the need for nuts in many cases. Moreover, these bolts can accommodate high-stress environments, making them suitable for use in heavy machinery and load-bearing structures. Understanding the properties and uses of high tensile carriage bolts can greatly enhance project outcomes, ensuring that the chosen fasteners meet the required strength and durability standards for specific tasks.

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

| Bolt Size | Material | Tensile Strength (MPa) | Length (mm) | Applications |

|---|---|---|---|---|

| M6 | Carbon Steel | 800 | 50 | Furniture, Automotive |

| M8 | Stainless Steel | 900 | 60 | Construction, Machinery |

| M10 | Alloy Steel | 1100 | 75 | Heavy Equipment, Automotive |

| M12 | High Carbon Steel | 1200 | 100 | Industrial Applications |

| M16 | Galvanized Steel | 1400 | 150 | Construction, Bridges |

Key Features of High Tensile Carriage Bolts: What to Look For

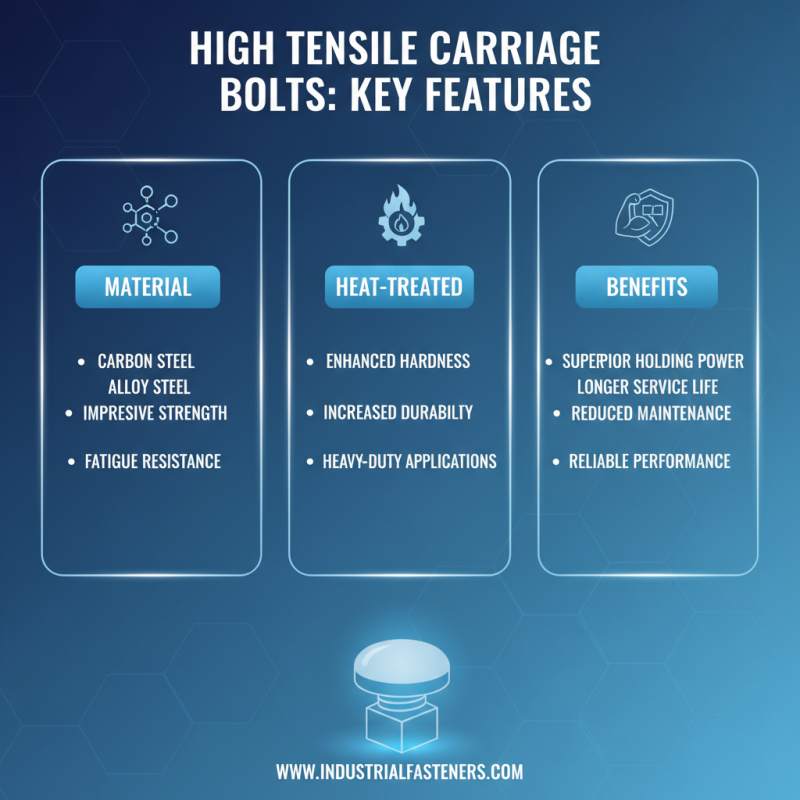

When selecting high tensile carriage bolts, it's essential to understand their key features that contribute to strength and durability. One of the primary factors to consider is the material composition. High tensile carriage bolts are typically made from carbon steel or alloy steel, both of which provide impressive strength and fatigue resistance. Look for bolts that are heat-treated, as this process enhances their hardness and overall durability, making them suitable for heavy-duty applications.

Another critical feature is the bolt's tensile strength, often measured in pounds per square inch (PSI). High tensile carriage bolts generally have higher tensile strengths compared to standard bolts, ensuring they can withstand significant loads without deforming. It's also important to check the finish of the bolts; options like hot-dipped galvanization or plated finishes can greatly increase corrosion resistance, making them ideal for outdoor and structural projects where exposure to moisture is a concern.

Additionally, the design of the bolt plays a vital role in its functionality. The square neck under the head prevents spinning when tightening, providing a secure grip in various applications. Ensure the bolts come in the appropriate lengths and diameters to suit your specific needs, as this can impact both their performance and the integrity of the connection they provide. These features collectively ensure that high tensile carriage bolts deliver the strength and durability required for demanding tasks.

Top Brands of High Tensile Carriage Bolts: A Comparative Review

When exploring the market for high tensile carriage bolts, various brands stand out due to their focus on strength and durability. Many manufacturers offer superior materials and manufacturing processes that contribute to the overall performance of their bolts. A comparative review of these brands reveals key differences in tensile strength, corrosion resistance, and overall longevity.

Pay attention to bolts that emphasize certifications and industry standards, as this often indicates a commitment to quality and performance.

Tips: Always check the specifications to ensure that the tensile strength meets your project requirements. Additionally, consider the coating used on the bolts; some coatings provide better protection against rust and wear, enhancing longevity in adverse weather conditions.

Furthermore, look for user reviews and expert recommendations to gauge the reliability of each brand. It can also be beneficial to consider the size and threading options available, as these factors can significantly impact the functionality and fit of the bolts in your specific applications. Opting for the right high tensile carriage bolts can make a significant difference in your projects, ensuring durability and safety in the long term.

Installation Tips for High Tensile Carriage Bolts: Best Practices

When installing high tensile carriage bolts, following best practices is crucial for maximizing strength and ensuring durability. One key aspect is to pre-drill the holes to match the diameter of the bolts. According to a study published by the American Society of Civil Engineers, proper hole preparation can significantly improve load distribution and prevent material splitting, thus extending the lifespan of the bolted connection. Additionally, using a lubricant on the bolt threads during installation can help achieve the necessary torque without excessive friction, which may lead to inaccurate tightening and diminished strength.

Another important practice is to select the appropriate grade of high tensile carriage bolts. Bolts are typically categorized by their tensile strength, with Grade 8 bolts offering approximately 150,000 psi in tensile strength, making them suitable for heavy-duty applications. Reports from the Industrial Fasteners Institute indicate that utilizing properly graded bolts aligned with the application’s requirements can reduce the risk of failure under stress. Furthermore, after installation, it’s advisable to perform periodic inspections and maintenance, as fatigue can lead to loosening over time, ensuring the integrity of the structure remains intact.

Strength Comparison of High Tensile Carriage Bolts

Maintenance and Care for Ensuring Durability of Carriage Bolts

Proper maintenance and care are essential for ensuring the durability of high tensile carriage bolts. These bolts, known for their exceptional strength, are often used in demanding applications. To maintain their integrity, it is crucial to regularly inspect the bolts for signs of wear, corrosion, or damage. Ensuring that the bolts are free from debris and contaminants can help prevent premature deterioration. Additionally, periodic tightening may be necessary to secure the connections, especially in environments subject to vibration or shifting.

Another key aspect of care involves the storage and environmental conditions in which carriage bolts are kept. It's important to store these bolts in a dry, moisture-free area to prevent rust formation. Using protective coatings, such as galvanization, can also significantly enhance their resistance to corrosion. In situations where carriage bolts are exposed to harsh elements, applying a lubricating oil can provide an additional layer of protection. By implementing these maintenance practices, you can significantly extend the lifespan and performance of high tensile carriage bolts in your projects.

Related Posts

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

How to Choose the Right Furniture Screw for Your DIY Projects

-

Top 2025 Furniture Screw Types: Which One is Right for Your Project?