Best Stainless Carriage Bolt Types for Your Projects?

Stainless carriage bolts are essential for many projects. Their durability and resistance to corrosion make them ideal for outdoor use. Choosing the right type can impact the strength and longevity of your work.

Various designs exist. Some feature a smooth, domed head, while others have a square neck that prevents rotation. Consider your project's needs carefully. The right selection may seem obvious but can require some reflection. Mistakes can lead to structural issues later on.

In the world of construction, small details matter. A stainless carriage bolt may seem simple, yet it plays a crucial role. This guide will help you navigate the options available, ensuring you make informed decisions for your projects.

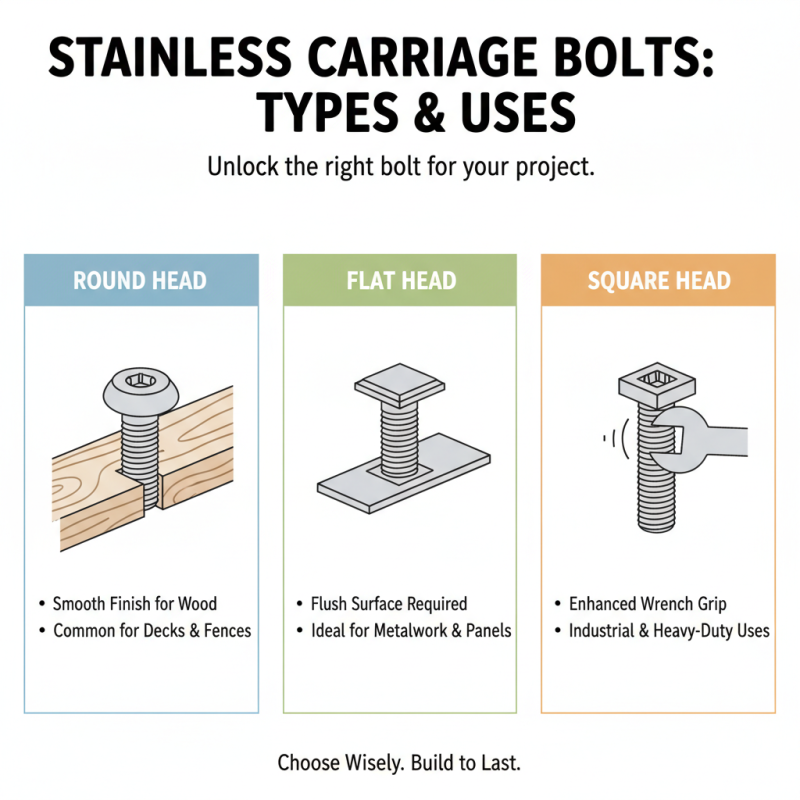

Types of Stainless Carriage Bolts: A Comprehensive Overview

When considering stainless carriage bolts for projects, understanding their types is crucial. The most common types include round head, flat head, and square head. Each type has unique applications. Round head bolts are excellent for wood, providing a smooth finish. Flat head bolts work well in situations requiring a flush surface. Square head bolts offer a better grip for wrench use.

A report from the Fastener Industry Study indicated that stainless steel bolts hold up well against corrosion. In many environments, they lasted more than a decade. However, the wrong choice can lead to structural failures. For instance, using a round head bolt in a high-stress area could cause problems. Data shows that 10% of projects suffer due to incorrect fastener choices.

Material composition matters too. The standard 304 stainless steel is popular, but 316 offers superior corrosion resistance. Despite its cost, 316 is often necessary in marine applications. Yet, there is a common misconception that all stainless steel is the same. Not understanding these differences can lead to overspending or failure in performance. Always consider the specific project needs.

Benefits of Using Stainless Steel in Carriage Bolt Applications

Stainless steel carriage bolts offer significant advantages in various applications. They are highly resistant to corrosion, which makes them perfect for outdoor projects. According to a study from the American Institute of Steel Construction, stainless steel can resist over 80% of corrosion compared to standard steel. This means longer-lasting projects and reduced maintenance costs.

Using stainless steel carriage bolts also enhances structural integrity. Their strength is well-documented. A report from the National Institute of Standards and Technology shows that stainless steel maintains its tensile strength even under high temperatures. This characteristic is vital for construction in fluctuating climates.

However, stainless steel can be more expensive than traditional materials. This price difference can influence budgets, especially in large projects. Not everyone considers this trade-off. It's a critical factor to weigh when planning. Over time, the durability may justify the initial cost, but calculations need careful deliberation. Choosing the right material impacts both performance and expense.

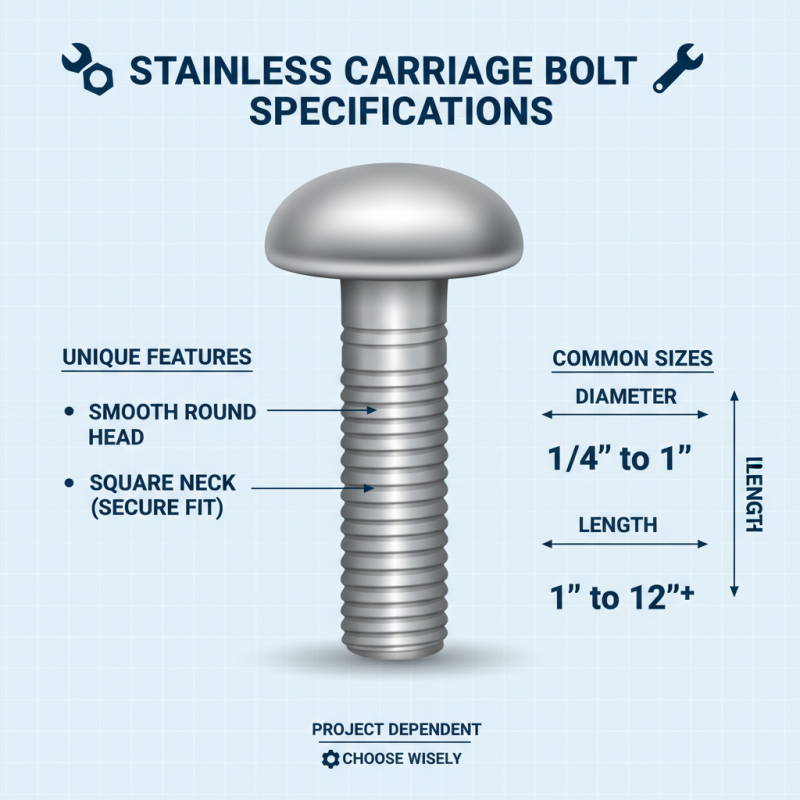

Key Specifications and Sizes for Stainless Carriage Bolts

When selecting stainless carriage bolts for your projects, key specifications matter greatly. These bolts have a smooth round head and a square neck for a secure fit. Common sizes range from 1/4 inch to 1 inch in diameter. The length can vary significantly, from 1 inch up to 12 inches or more. Each project will dictate the ideal size and length.

Corrosion resistance is another vital specification. Stainless steel offers durability and longevity, but not all grades are equal. Grade 304 is common, but grade 316 provides even better resistance in harsh environments. The type of application should inform your choice of grade. For example, outdoor projects benefit from higher corrosion resistance.

It’s essential to consider your project’s specific needs. If using larger bolts, ensure you have compatible nuts and washers. Sometimes, the ideal size may not be readily available. In those cases, think creatively about adjustments. It’s crucial to double-check measurements and test fitments. Small oversights can lead to significant delays.

Comparative Strength: Stainless Carriage Bolts vs. Other Materials

Stainless carriage bolts stand out when compared to bolts made from other materials. Their resistance to rust and corrosion makes them ideal for outdoor projects. Unlike carbon steel bolts, stainless steel doesn't need extra coatings. This saves time and effort. The natural shine of stainless steel is aesthetically pleasing too.

When considering strength, stainless carriage bolts can handle loads effectively. They offer high tensile strength. However, they can be less strong than hardened steel bolts. This can limit their use in extreme conditions. Evaluating the specific requirements of a project is crucial. For heavy-duty applications, choose according to load capacity.

Tip: Use stainless carriage bolts in humid environments. This choice will extend the lifespan of your project. Also, ensure proper installation. Tightening them too much may cause breakage. Understanding the nuances of materials is key to success.

Installation Techniques for Optimal Performance of Stainless Carriage Bolts

When working with stainless carriage bolts, proper installation is key for success. Start by ensuring the surfaces you’re joining are clean and free from debris. Use a drill to create the right-sized hole for the bolt. This step is critical; too tight and you can damage the material. Too loose, and the bolt won't hold firmly. Remember to consider the length and diameter of the bolt. Having the right size matters.

Using a washer is another smart move. It helps distribute the load and prevents the bolt from pulling through the material. Place the washer under the bolt head and, if applicable, also under the nut. Tighten the nut carefully, but be cautious not to overdo it. Over-tightening can lead to stripping and weak connections. Some trial and error is expected, especially if you are new to this.

Don't overlook the importance of lubrication, either. A little anti-seize compound on the threads can go a long way. This technique helps prevent rust and makes future removals easier. Keep in mind, sometimes bolts break. If that happens, reflect on the installation process. Learning from these moments helps you improve skills.

Best Stainless Carriage Bolt Types for Your Projects

This chart represents the performance ratings of different types of stainless carriage bolts based on tensile strength and corrosion resistance. Each type is evaluated for its suitability in various applications.

Related Posts

-

How to Choose the Right Stainless Bolt for Your Project?

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

Top 10 Types of Furniture Fasteners You Need to Know?

-

What is a Furniture Fastener and Why is it Essential for Your Setup?

-

How to Choose the Right Furniture Screw for Your DIY Projects