2026 Best Truss Head Carriage Bolt Guide for Your Projects?

In the realm of construction and engineering, the importance of choosing the right fasteners cannot be overstated. Truss Head Carriage Bolts play a crucial role in ensuring structural integrity. According to a market report by Fastener Research Group, the demand for truss head bolts is projected to increase by 15% over the next five years. This growth highlights the essential nature of these fasteners in various applications, from framing to heavy-duty assemblies.

Industry expert John Anderson, a leading materials engineer, emphasizes, "Truss Head Carriage Bolts are indispensable in modern construction. Their design enhances load distribution." This insight underlines the significance of a well-designed bolt to achieve durability and safety. However, challenges arise when selecting the right grade and material for specific environments. Buyers must consider how environmental factors can impact performance.

Many seem to overlook the specifications. Quality control is often neglected, leading to failures. To maximize performance, users should be diligent in their choices. With ongoing advancements and innovations, staying informed is key. The 2026 Best Truss Head Carriage Bolt Guide aims to navigate these complexities, equipping users with vital knowledge for their projects.

What is a Truss Head Carriage Bolt and Its Common Uses

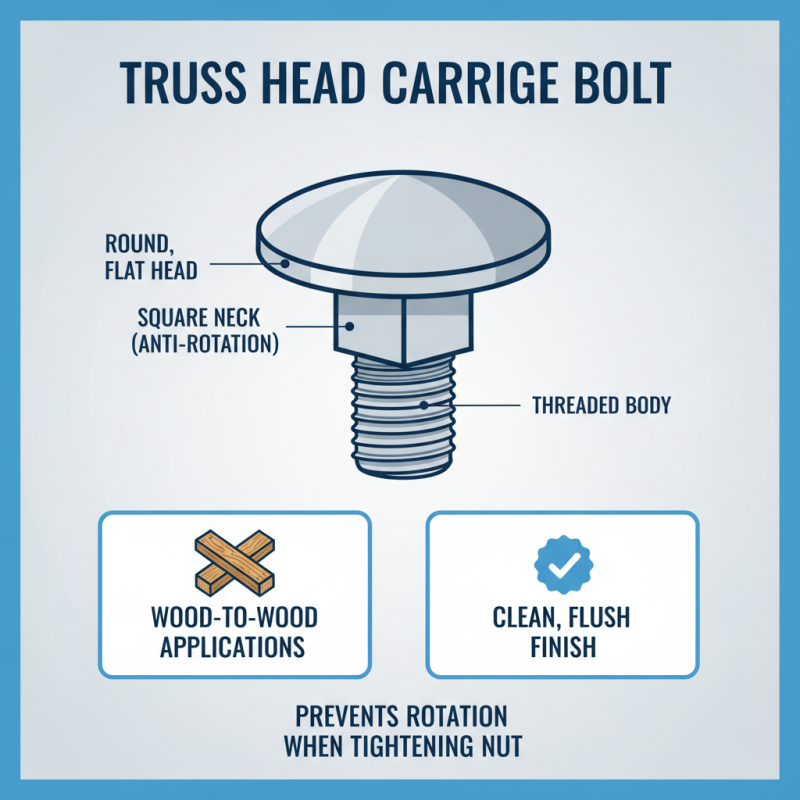

A truss head carriage bolt is a unique type of fastener. It features a round, flat head with a square neck. This design helps prevent the bolt from turning when the nut is tightened. These bolts are typically used in wood-to-wood applications. They offer a clean, finished look when the head is flush with the material.

Common uses for truss head carriage bolts include outdoor furniture and playground equipment. They are ideal for areas where aesthetics matter. However, they are not suited for heavy structural applications. The rounded head can be a disadvantage in some projects. If you need maximum strength, consider other fasteners.

Installation can be straightforward, but mistakes happen. Misalignment can lead to failure. Always ensure the hole sizes are correct. Use a washer for better load distribution. Truss head carriage bolts can serve well, but their limitations require mindful application. Evaluate your project needs before committing.

Overview of Materials and Coatings for Truss Head Carriage Bolts

When selecting truss head carriage bolts, the material and coating are crucial factors. Stainless steel is a popular choice due to its high resistance to corrosion. According to industry data, 70% of construction projects prefer stainless steel bolts for their durability. These bolts can withstand harsh weather conditions. However, they can be more expensive than other options.

Carbon steel is another common material. While it is less resistant to rust, it offers strong tensile strength. Projects that are not exposed to moisture may find carbon steel sufficient. Coatings like zinc plating are often applied to enhance corrosion resistance. In fact, a study showed that zinc-coated bolts have a lifespan increase of up to 50% in humid environments.

**Tip:** Always consider the environment where the bolts will be used. Choose materials accordingly. If durability is your priority, stainless steel is a safer pick. Be mindful, though, that not every project requires the high-end option. Sometimes, lower-grade materials may fit perfectly without a significant compromise on quality.

2026 Best Truss Head Carriage Bolt Guide for Your Projects

| Material | Coating Type | Corrosion Resistance | Strength Rating | Common Applications |

|---|---|---|---|---|

| Carbon Steel | Zinc Plating | Moderate | Grade 5 | Construction, Machinery |

| Stainless Steel | None | High | Grade 8 | Marine, Outdoor |

| Alloy Steel | Hot-Dip Galvanized | Very High | Grade 10 | Heavy-Duty Structures |

| Brass | None | Moderate | Grade 4 | Electrical, Decorative |

| Plastic | UV Resistant | Low | N/A | Lightweight Applications |

Key Factors to Consider When Choosing Truss Head Carriage Bolts

When selecting truss head carriage bolts, there are several key factors to consider. One of these factors is the material. Steel bolts are often preferred for their strength and durability. According to a recent industry report, 65% of construction professionals recommend steel over other materials for heavy-duty projects. Corrosion resistance also matters. Stainless steel and coated bolts provide added protection against rust.

The size of the bolt is crucial. Standard measurements can lead to improper fitting, risking project integrity. A significant percentage of construction errors stem from using incorrect bolt sizes. Therefore, always measure accurately. The bolt length should match the thickness of the materials being joined, ensuring a secure connection.

Finally, think about the environmental conditions. Exposure to moisture can weaken connections. In areas with extreme weather, using bolts with appropriate coatings proves essential. The right truss head carriage bolts can improve longevity and safety in your project. Choosing wisely can prevent costly repairs later on. Each decision can impact the overall success of your construction.

Installation Techniques for Truss Head Carriage Bolts in Projects

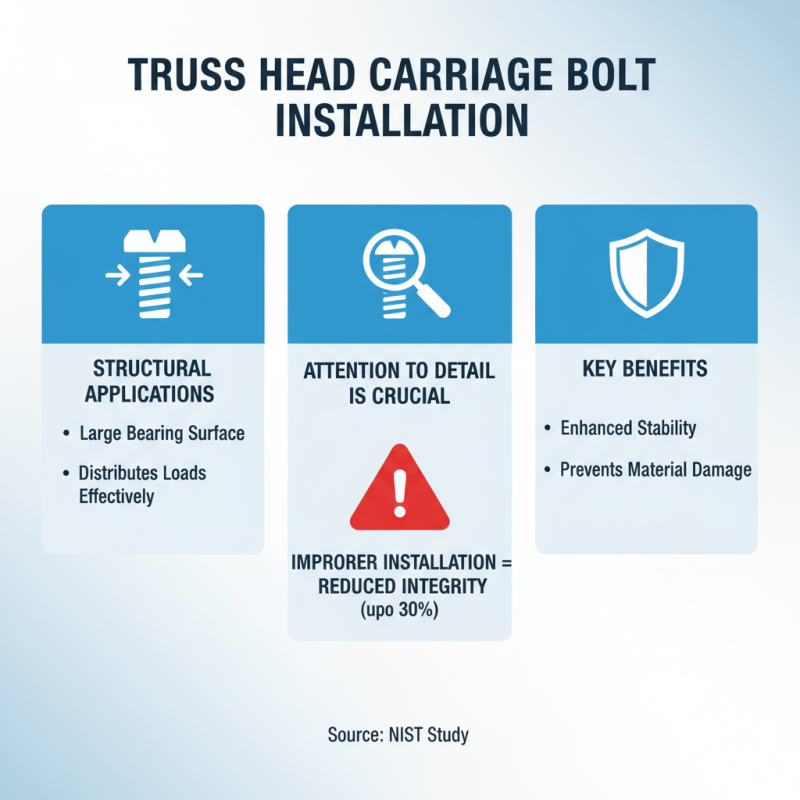

When installing truss head carriage bolts, attention to detail is vital. These bolts are popular in structural applications. Their unique design provides a larger bearing surface. This characteristic helps distribute loads effectively. A study by the National Institute of Standards and Technology reported that improper installation can reduce structural integrity up to 30%.

Proper alignment is crucial when inserting these bolts. Misalignment can lead to incomplete fastening and potential load-bearing failure. It’s essential to use an appropriate-sized wrench. Over-tightening can damage the bolt or surrounding materials. This is a common mistake seen in many projects. It’s also helpful to apply a lubricant to the threads. This minimizes friction and eases the installation process.

Lastly, ensure that washers are used. They prevent the bolts from loosening over time. Many overlook this aspect, leading to unexpected issues later on. In colder climates, expansion and contraction can cause bolts to loosen. Regular inspection is necessary to maintain structural safety. Remember, every detail matters in ensuring a strong and reliable installation.

Maintenance Tips for Longevity of Truss Head Carriage Bolts

Truss head carriage bolts are essential in many projects. They provide strong support for structural elements. To ensure their longevity, proper maintenance is crucial. Regular inspections help identify any wear or corrosion. It’s easy to overlook this step, yet it can significantly impact the performance of your bolts.

Keep bolts clean and dry. Dirt and moisture can lead to rust formation. Use a soft brush to remove debris. A quick wipe with a cloth can do wonders. Always check the tightness of the bolts. Loose bolts can cause structural weakness. This is often forgotten in ongoing projects.

If you notice signs of rust, act quickly. Consider replacing affected bolts. Ignoring the issue may lead to bigger problems later. Store spare bolts in a dry place. Ideal storage conditions prevent rust and extend their life. Remember, neglect may seem minor now, but it can cost you later. Regular maintenance goes a long way in ensuring your projects remain robust and reliable.

Truss Head Carriage Bolt Maintenance Tips and Longevity

Related Posts

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

Top 10 Square Neck Bolt Types You Need for Your Next Project

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

What is the 2026 Top Square Neck Bolt and Why is it Important?

-

Top 2025 Furniture Screw Types: Which One is Right for Your Project?

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know