How to Choose the Best High Quality Carriage Bolt for Your Project

When embarking on a project that requires durable and reliable fastening solutions, choosing the right components is critical. Among these, the "High Quality Carriage Bolt" stands out for its effectiveness and versatility across various applications. According to John Smith, a leading expert in fastening technology, "The selection of the right high-quality carriage bolt can significantly impact the long-term durability and stability of your project." This emphasizes the importance of not only understanding the basic properties of carriage bolts but also recognizing the specific features that distinguish high-quality options from their lower-grade counterparts.

The significance of using a high-quality carriage bolt cannot be overstated, as it not only ensures structural integrity but also enhances the overall safety of your work. Factors such as material composition, finishing processes, and design specifications play a crucial role in determining the quality of these fasteners. As we delve deeper into the characteristics that define a high-quality carriage bolt, the goal is to equip you with the knowledge necessary to make informed choices tailored to your project needs, ultimately leading to successful and sustainable outcomes.

Understanding Carriage Bolts: Types and Uses in Construction

Carriage bolts, also known as round head bolts, are essential fasteners commonly used in construction and woodworking projects due to their unique design and versatility. Unlike traditional bolts, carriage bolts feature a smooth, rounded head that prevents them from slipping through a hole, making them ideal for securing wood pieces together. Their square necks are designed to embed into the material, providing a firm grip that is particularly advantageous in applications requiring high tensile strength.

According to a report by the Industrial Fasteners Institute, carriage bolts account for a significant portion of the fastener market, with usage projected to grow by 4% annually over the next five years. This steady demand is driven by the increasing popularity of DIY projects and the expanding construction industry. Carriage bolts come in various materials, including stainless steel and galvanized finishes, allowing for applications in both indoor and outdoor environments. Their durability makes them suitable for heavy-duty applications, such as connecting wooden beams in decks or securing heavy machinery in industrial settings, where both structural integrity and resistance to weather conditions are critical. Understanding the types and specific uses of carriage bolts can significantly enhance the quality and longevity of construction projects.

How to Choose the Best High Quality Carriage Bolt for Your Project

| Bolt Type | Material | Size (Diameter) | Length (inches) | Typical Use |

|---|---|---|---|---|

| Standard Carriage Bolt | Carbon Steel | 1/4" | 2" | Wood Applications |

| Heavy-Duty Carriage Bolt | Stainless Steel | 3/8" | 4" | High-Stress Applications |

| Galvanized Carriage Bolt | Galvanized Steel | 5/16" | 3" | Outdoor Applications |

| Square Head Carriage Bolt | Mild Steel | 1/2" | 6" | Construction and Framing |

| High-Strength Carriage Bolt | Alloy Steel | 1/2" | 8" | Industrial Applications |

Key Factors to Consider When Selecting High-Quality Carriage Bolts

When selecting high-quality carriage bolts for your project, several key factors should be taken into account. First and foremost is the material of the bolt. Common materials include steel, stainless steel, and even plastic options. Steel bolts offer strength and durability, but consider stainless steel if corrosion resistance is a priority, especially for outdoor projects or those exposed to moisture. The finish of the bolt is also important; zinc plating can enhance resistance to rust, while hot-dipped galvanization provides an even more robust protective layer.

Another critical factor is the size and length of the carriage bolt. Ensure that the length is appropriate for your intended application, allowing for adequate embedding into the material while also accommodating any washers or nuts necessary for securing the bolt. The diameter of the bolt should match the requirements of your project, as a bolt that is too thin may not provide the necessary support, while one that is too thick can cause unnecessary damage to the materials being joined.

Finally, evaluating the quality of the threading is essential. High-quality bolts will typically feature uniform, deep, and sharp threads that facilitate easier assembly and provide better grip. Inspecting these factors before making a selection can significantly enhance the overall integrity and longevity of your project, ensuring that the carriage bolts serve their intended purpose effectively.

Material Selection for Durability: Choosing the Right Steel Grade

When selecting carriage bolts for a project, the choice of

steel grade is crucial for ensuring

durability and reliability. Typically, there are various grades of steel available, such as

ASTM A307, A36, and A325, each with distinct properties that cater

to different applications. According to industry reports, A36 steel, known for its good

weldability and tensile strength ranging from 58,000 to 80,000 psi, is a versatile choice for

general construction and structural applications. However, when extreme conditions or heavy loads are

expected, opting for higher-grade steel like A325, which has a minimum yield strength of

65,000 psi, can significantly enhance structural integrity.

When selecting carriage bolts for a project, the choice of

steel grade is crucial for ensuring

durability and reliability. Typically, there are various grades of steel available, such as

ASTM A307, A36, and A325, each with distinct properties that cater

to different applications. According to industry reports, A36 steel, known for its good

weldability and tensile strength ranging from 58,000 to 80,000 psi, is a versatile choice for

general construction and structural applications. However, when extreme conditions or heavy loads are

expected, opting for higher-grade steel like A325, which has a minimum yield strength of

65,000 psi, can significantly enhance structural integrity.

In addition to mechanical properties, resistance to environmental factors is another aspect of material selection that cannot be overlooked. Corrosion resistance is vital, especially for outdoor projects, where exposure to moisture can lead to deterioration. Studies by the American Institute of Steel Construction indicate that galvanizing steel can increase its lifespan by more than 50%, making it an indispensable option in areas prone to harsh weather. Thus, choosing the right steel grade not only enhances the strength of the carriage bolt but also contributes to its longevity, ensuring that your project stands the test of time.

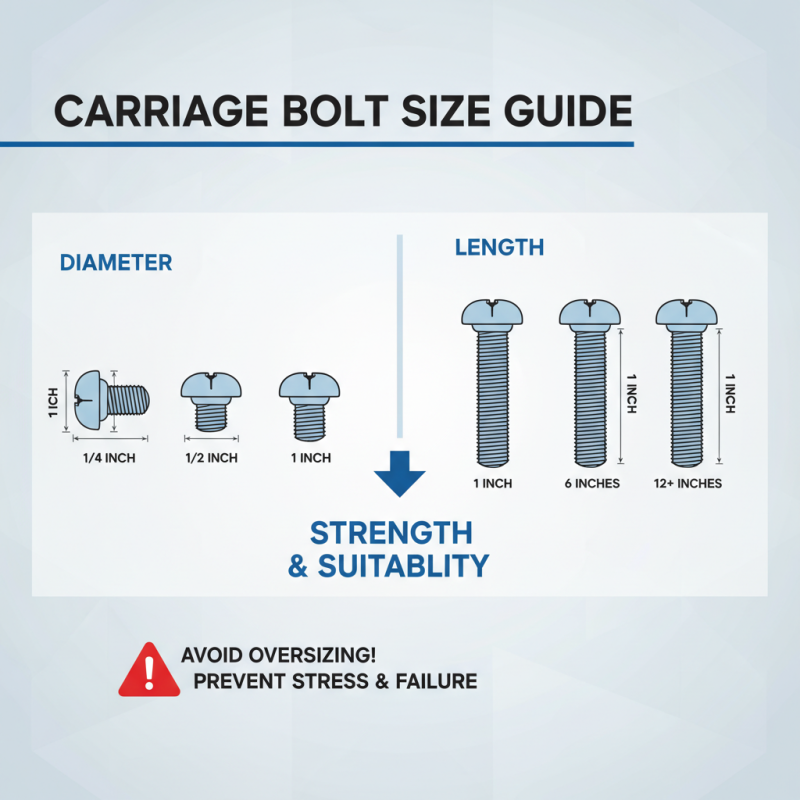

Size Matters: How to Determine the Appropriate Bolt Length and Diameter

When selecting the right carriage bolt for your project, understanding the importance of size is crucial. The length and diameter of the bolt significantly impact not only its strength but also its suitability for specific applications. Typically, carriage bolts are available in a range of diameters, from 1/4 inch to 1 inch and lengths that can span from just 1 inch to over 12 inches. According to the American Forest & Paper Association, using oversized bolts can lead to unnecessary stress and potential failure points in structural applications. Therefore, it's essential to determine the exact length and diameter needed based on the materials being joined and the load the joint will support.

Tips: Measure the thickness of the materials you’ll be fastening together and select a bolt length that will extend at least 1 inch beyond the surface of the materials to ensure adequate thread engagement. Additionally, when it comes to diameter, a general rule is to select a bolt that is approximately 1/8 inch larger than the hole size for best results, which helps accommodate for any manufacturing variances and ensures a secure fit.

The proper selection of carriage bolt size can also influence the overall aesthetics and functionality of your project. Bolts that are too large can lead to an unsightly appearance and may not provide the desired clamping force. Conversely, bolts that are too small might not withstand the required loads, leading to potential structural integrity issues. The Engineering Toolbox indicates that the correct bolt diameter combined with appropriate nut and washer sizes can preserve joint integrity while maintaining an efficient application—ensuring that the final assembly is both strong and visually appealing.

Installation Tips for Optimal Performance of Carriage Bolts

When installing carriage bolts, ensuring optimal performance is key to the success of your project. Start by pre-drilling holes in the materials you plan to fasten. This not only makes installation smoother but also reduces the risk of splitting the wood or damaging other materials. Choose a drill bit that matches the diameter of your carriage bolt’s shaft, and maintain a steady hand to create clean, precise holes.

Once the holes are ready, insert the carriage bolts through the aligned holes, ensuring that the rounded head is on the outer side. This allows for a clean finish and prevents snagging. When securing the nut on the opposing side, use a washer to distribute the load and prevent damage to the material. Tighten the nut gradually, checking for proper alignment and ensuring that the bolt does not pull through the material. Applying the correct torque is vital; too tight can warp the materials, while too loose may compromise the integrity of the connection. Following these tips will help achieve a secure and long-lasting installation of your carriage bolts.

Carriage Bolt Quality Comparison

Related Posts

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

How to Choose the Right Furniture Screw for Your DIY Projects

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

How to Use Torx Screws for Effective and Secure Fastening Solutions