How to Choose High Tensile Carriage Bolt for Your Projects?

Choosing the right hardware can define the success of any project. High Tensile Carriage Bolts are essential for many construction applications. They offer strength and durability that standard bolts may lack. As John Axton, a leading expert in the fastening industry, stated, "Selecting the right bolt is crucial; otherwise, your project may face unforeseen failures."

When considering High Tensile Carriage Bolts, one must look at the material and load ratings. Quality matter. A well-made bolt meets specific standards, making it suitable for heavy loads. Often overlooked, the bolt's length and diameter also play significant roles in structural integrity. Flaws in these aspects can lead to weak connections.

Another aspect is resistance to corrosion. Some projects may expose bolts to harsh environments. It's crucial to choose bolts that can withstand such conditions. Inadequate choices can lead to premature failures. Therefore, investing time in understanding High Tensile Carriage Bolts is essential.

Understanding High Tensile Carriage Bolts and Their Use Cases

High tensile carriage bolts are essential in many construction and project applications. These bolts are designed to withstand high loads and provide reliable strength. They are often used in wood and metal connections, making them versatile for various projects. Understanding their material properties is crucial. High tensile steel, commonly used for these bolts, offers increased strength compared to standard steel.

When selecting high tensile carriage bolts, consider the environment. Will they be exposed to moisture? Corrosion-resistant finishes are ideal for outdoor use. Tips: always check load ratings to ensure safety.

Another aspect to think about is the size. Proper length and diameter are vital for secure fastening. Using bolts that are too short can lead to failures. In contrast, oversized bolts may require excessive drilling. Tips: measure accurately and do not rush this process.

While high tensile carriage bolts are valuable, they are not always the answer. Analyze project requirements first. Some applications might benefit from other fasteners. Bolts can be overkill in smaller projects. Tips: evaluate the specific needs before deciding. Consider alternatives if you find high tensile bolts excessive or impractical. Keep your projects practical and efficient by choosing the right fastener.

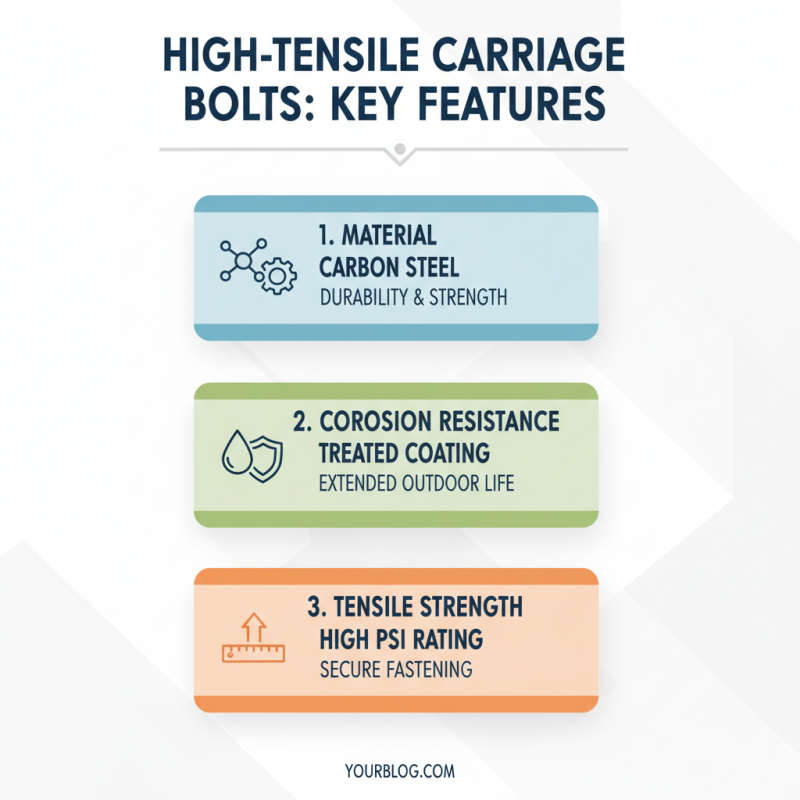

Identifying the Key Features of High Tensile Carriage Bolts

Choosing high tensile carriage bolts requires careful consideration of several key features. Pay attention to the material used. High tensile bolts are often made from carbon steel, which offers durability. Look for bolts that are treated for corrosion resistance. This can extend the life of your project, especially in outdoor settings.

When examining the tensile strength, aim for a rating that meets your project's demands. Many high tensile bolts have a yield strength that can withstand heavy loads. Verify that the bolts have been manufactured to relevant standards, such as ASTM or ISO certifications. This can provide assurance of their quality.

Tips: Always measure the length needed accurately. A bolt that is too long or short can affect structural integrity. Consider the thread type as well. Coarse threads provide better grip in softer materials. Test different options if available. This helps refine your decision for the best fit. Don't rush this process; evaluate the features carefully before making a choice.

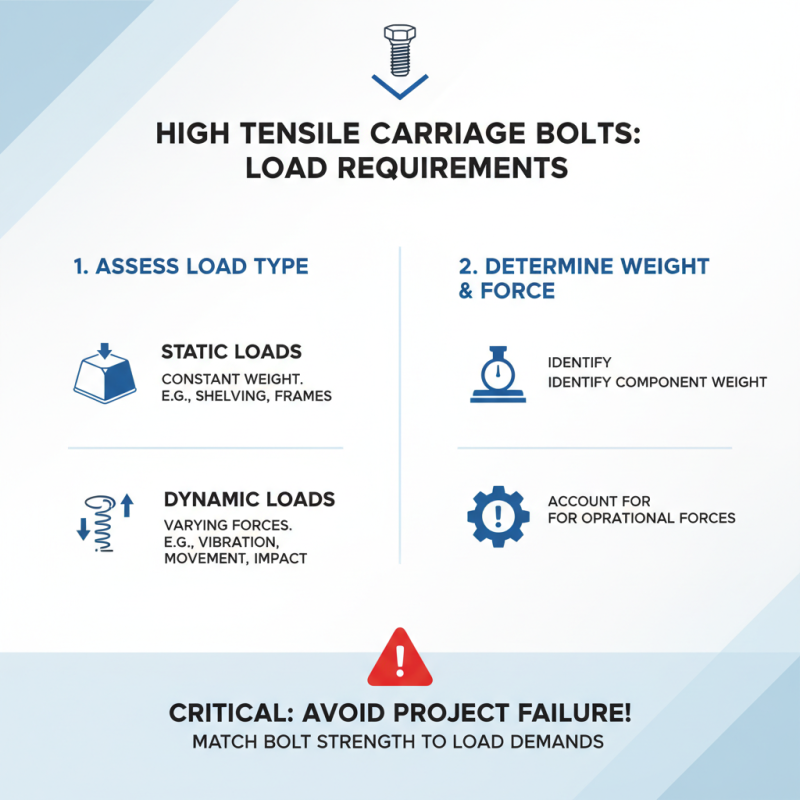

Assessing Load Requirements for Your Project

When choosing high tensile carriage bolts, assessing load requirements is crucial. These bolts serve various purposes and must handle specific forces. Start by identifying the weight of the components they will secure. Consider both static and dynamic loads. Static loads don't change, while dynamic loads vary during operation. A failure in understanding this can lead to potential project disasters.

Next, think about safety margins. It's wise to avoid pushing the limits of your selected bolt. Safety factors ensure that unexpected forces won’t compromise your project’s integrity. If you're unsure about calculations, it's better to consult engineering guidelines or seek expert advice.

Also, analyze the environment where the bolts will be used. Factors like moisture, temperature, and exposure to chemicals affect bolt performance. Installing bolts in unsuitable conditions may lead to premature failure. Take your time to reflect on these considerations. It can save you from costly mistakes later on.

Selecting the Right Material and Coating for Durability

Choosing the right material and coating for high tensile carriage bolts is crucial for any project. The material greatly influences strength. Common options include carbon steel, stainless steel, and alloy steel. Each material has unique properties. Carbon steel offers strength but can rust. Stainless steel resists corrosion but may not handle heavy loads well. Alloy steel brings both strength and durability, but its cost can be higher.

Coating plays a significant role in enhancing durability. Galvanization is a popular choice, providing a layer of zinc to prevent rust. Ideal for outdoor projects, it can make a big difference. However, varying thicknesses in coating can lead to inconsistent performance. Powder coating offers aesthetic appeal but may chip or wear off over time. Consider your project needs carefully. Factors like exposure to moisture and weight load should be taken into account.

Reflecting on these materials and coatings is essential. Sometimes, the best option seems unclear. A cheaper material might save money initially but could lead to future issues. Think about long-term implications. Don't overlook the importance of proper installation. Even the best materials can fail if not secured correctly. Balancing cost, durability, and project requirements is a complex task.

How to Choose High Tensile Carriage Bolt for Your Projects? - Selecting the Right Material and Coating for Durability

| Material | Coating Type | Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|

| Carbon Steel | Zinc Plated | 400 | Moderate | Construction, Furniture |

| Stainless Steel | Passivated | 600 | High | Marine, Outdoor Equipment |

| Alloy Steel | Black Oxide | 800 | Low | Automotive, Heavy Machinery |

| Brass | None | 340 | Moderate | Plumbing, Decorative Hardware |

Evaluating Sizing and Length Considerations for Proper Fit

Choosing the right size and length for high tensile carriage bolts is crucial for project success. The bolt's diameter must match the material thickness. Typically, a tighter fit ensures better load distribution and reduces the risk of failure. According to industry reports, using the correct bolt diameter can enhance structural integrity by up to 30%.

When considering bolt length, factor in the material's thickness, washers, and nut height. The general rule of thumb is to add at least one inch to the total thickness of the materials being fastened. This allows for a secure connection without excessive protrusion. Remember, longer bolts may lead to unnecessary weight and possible misalignment.

Tips: Always double-check your measurements. A slight miscalculation can lead to project delays. Additionally, account for any potential adjustments that may be needed later. Test your chosen bolt in a small-scale model. This can help identify issues before committing to the final design. Even experienced builders make mistakes. Reflection on your choices can lead to better outcomes.

High Tensile Carriage Bolt Sizing and Length Considerations

Related Posts

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

Best High Tensile Carriage Bolt Applications and Benefits?

-

What is the 2026 Top Square Neck Bolt and Why is it Important?

-

Top Nut And Bolt Types for 2026 What You Need to Know?

-

How to Choose the Right Furniture Screw for Your DIY Projects