How to Choose the Right Stainless Bolt for Your Project?

When selecting the right stainless bolt for your project, several factors must be considered. Stainless bolts are essential in a range of applications due to their resistance to corrosion and strength. According to the Fastener Industry Study 2023, the demand for stainless steel fasteners is projected to grow by 5% annually. This indicates a significant trend in the industry, reflecting the material's increasing importance.

Choosing the correct stainless bolt is not just about material. Specifications such as size, thread type, and finish also matter. The Global Fastener Report highlights that improperly chosen fasteners can lead to project failure, resulting in costly repairs. In fact, nearly 30% of project delays stem from the use of wrong components, emphasizing the need for careful selection.

While it's clear that stainless bolts offer benefits, it's crucial to avoid overlooking details. Think about the environment where the bolts will be used. Factors like temperature and exposure to chemicals can affect performance. In the end, the right stainless bolt can enhance durability, but an ill-informed choice might lead to issues. Always reassess your options and gather accurate information before making a decision.

Understanding Different Types of Stainless Steel Bolts

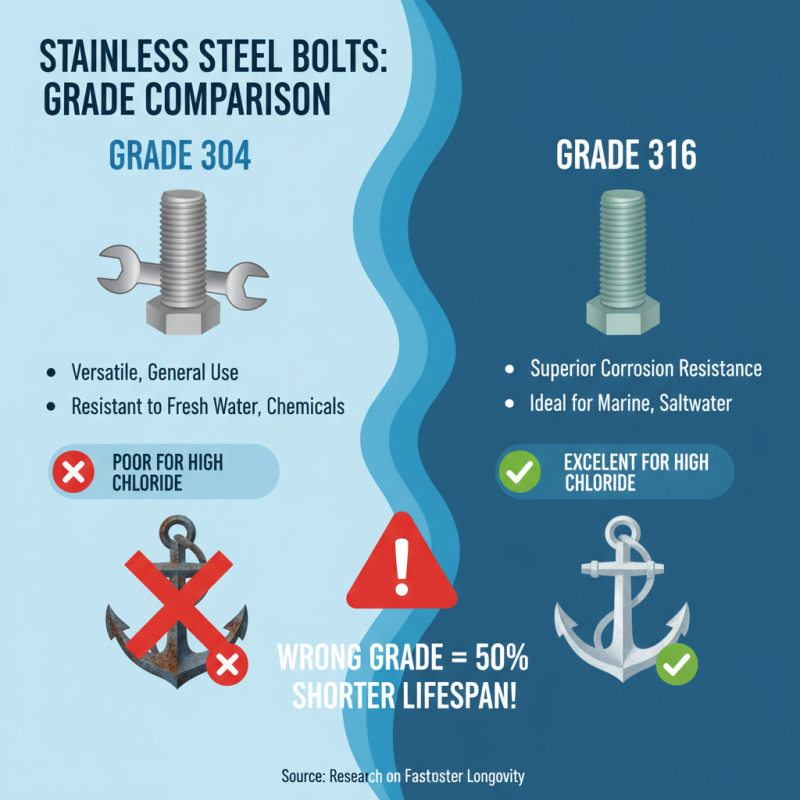

When selecting stainless steel bolts, understanding the different types is crucial. Common grades include 304 and 316. Grade 304 is versatile and can handle many environments. However, it struggles with high chloride situations. On the other hand, grade 316 offers superior corrosion resistance. It is ideal for marine applications. Research shows corrosion can reduce the lifespan of fasteners significantly. In some cases, it might drop by 50% if the wrong grade is used.

There are also variations in bolt finishes. For instance, passivated bolts undergo a process that enhances corrosion resistance. Yet, not all projects require this level of protection. Understanding your project's environment is key. A study from the Fastener Quality Act indicates that improper bolt selection results in increased costs. Additionally, it often leads to project delays.

It is essential to consider the bolt's tensile strength, too. Different applications may demand various strength levels. For example, structural applications generally require bolts with higher strength ratings. However, using overly strong bolts can lead to issues like stress concentrations. This might lead to failures in critical areas. Therefore, finding a balance is important. Make informed decisions based on your specific needs and conditions.

Evaluating Strength and Corrosion Resistance for Your Application

Choosing the right stainless bolt involves more than just picking any option. Evaluating strength and corrosion resistance is essential for your specific application. Stainless steel comes in various grades, each with unique properties. Understanding these grades helps ensure you select an appropriate bolt.

Consider the environment where the bolt will be used. Will it face exposure to saltwater or chemicals? Choosing the wrong corrosion resistance can lead to failures. Marine-grade stainless steel, for instance, offers superior resistance in harsh environments.

**Tip:** Always check the tensile strength of the bolt. A bolt may look suitable, but it could fail under heavy loads.

Remember that surface finish affects corrosion resistance too. A dull finish may not perform as well as a polished one. Sometimes, the most visually appealing option isn’t the best for durability.

**Tip:** Verify the manufacturing processes of bolts. Look for inconsistencies. A poorly made bolt can impact your project’s success.

Taking the time to evaluate these factors will yield better results. Ideal choices today can prevent issues down the line.

How to Choose the Right Stainless Bolt for Your Project? - Evaluating Strength and Corrosion Resistance for Your Application

| Bolt Type | Material | Tensile Strength (MPa) | Corrosion Resistance | Common Uses |

|---|---|---|---|---|

| Hex Bolt | 304 Stainless Steel | 520 | Good | General fastening |

| Socket Cap Screw | 316 Stainless Steel | 579 | Excellent | Marine applications |

| Carriage Bolt | 410 Stainless Steel | 480 | Moderate | Wood to metal fastening |

| Lag Bolt | 304 Stainless Steel | 500 | Good | Heavy timber fastening |

| Eye Bolt | 316 Stainless Steel | 580 | Excellent | Lifting applications |

Selecting the Right Size and Length for Your Project Needs

Choosing the right size and length for stainless bolts can significantly impact your project’s success. When selecting bolts, measure carefully. Know the specific dimensions you need. The length of the bolt should go beyond the material you are fastening. A good rule is to add about a quarter inch past the thickness of the connected materials.

Tip: Always have a few extra bolts on hand. You never know when you might miscalculate or face unforeseen circumstances. Using a bolt that is too short can lead to instability. Conversely, a bolt that is too long can be awkward and may need to be cut.

Consider the diameter as well. The correct diameter ensures a secure fit. Bolts that are too thick can cause damage; too thin may not hold properly. Check the compatibility with your nuts and washers, too. An improper fit can cause issues later in your project. Remember that sometimes, it’s better to test out a few sizes before making a final decision. It can save you time and frustration down the road.

Recognizing Coating Options and Their Benefits

When choosing a stainless bolt, understanding coating options is essential. Various coatings offer different benefits. For instance, zinc plating provides corrosion resistance, but it's not suitable for all environments. In high-humidity areas, stainless bolts without coatings might perform better. A clear understanding of these environments helps prevent unexpected failures.

Additionally, powder coating offers durability. It can withstand physical abrasion and impact, extending a bolt's lifespan. However, the application process requires careful consideration. If not applied correctly, the coating may chip or peel off. This leads to compromised performance, which is a concern for many projects.

Another option is passivation, enhancing corrosion resistance through a chemical process. This makes stainless bolts more resilient against rust and tarnishing. However, keep in mind the potential cost and time implications. Projects with tight deadlines might struggle with these considerations. A balance between performance and practicality is vital. Make sure to evaluate all aspects before making a choice.

Assessing Cost Factors and Sourcing Options for Stainless Bolts

When selecting stainless bolts, cost factors must be thoroughly examined. The price of stainless steel can fluctuate. Recent reports indicate that raw material costs have increased by approximately 15% over the past year. This is mainly due to supply chain disruptions and increased demand in various sectors. Understanding market trends can help project budgets.

Sourcing options also play a key role. Online platforms and local suppliers both present unique advantages. According to industry analyses, purchasing in bulk can lead to cost savings of up to 20%. Yet, relying solely on online sources may lead to compromises in quality. Smaller, local suppliers might offer better customization and support but at a higher price point.

Evaluate shipping costs, lead times, and minimum order quantities before making decisions. Some suppliers have hidden fees—this can sneak up on your project budget. Compare multiple quotes and consider long-term relationships with suppliers to enhance reliability. Recognizing the trade-offs is essential. The balance between cost and quality can determine project success.

Related Posts

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

What is a Furniture Fastener and Why is it Essential for Your Setup?

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

What is the 2026 Top Square Neck Bolt and Why is it Important?