10 Essential Tips for Using Carriage Bolts Effectively?

Carriage bolts play a vital role in various construction and woodworking projects. Experts emphasize their importance for secure fittings. John Smith, a leading authority in fasteners, once said, "Carriage bolts provide strength where it matters most." Understanding how to use these fasteners effectively can make a significant difference in your work.

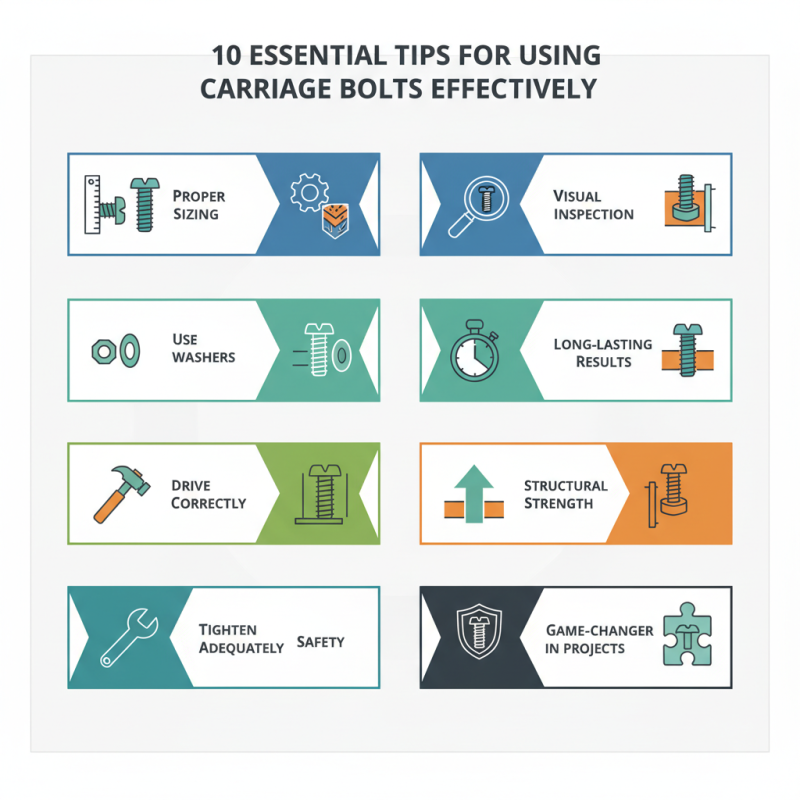

When using carriage bolts, consider proper sizing first. The wrong size can lead to structural weaknesses. Pay attention to the materials you are working with, as the bolt needs to match them. Often, people overlook the importance of washer use. A washer can improve the hold and reduce wear.

It’s also critical to drive the bolt correctly. Improper installation may cause the bolt to loosen over time. Many users fail to tighten bolts adequately, leading to safety issues. Visual inspection after installation is essential. It's easy to miss these details but vital for ensuring long-lasting results. Carriage bolts, when used correctly, can be a game-changer in many projects.

Understanding Carriage Bolts and Their Applications

Carriage bolts are unique fasteners with a rounded head and square neck. This design keeps them from spinning when tightened. They are commonly used in wood, metal, and composite materials. Their applications range from furniture assembly to constructing decks. Understanding how to use them correctly can enhance your projects.

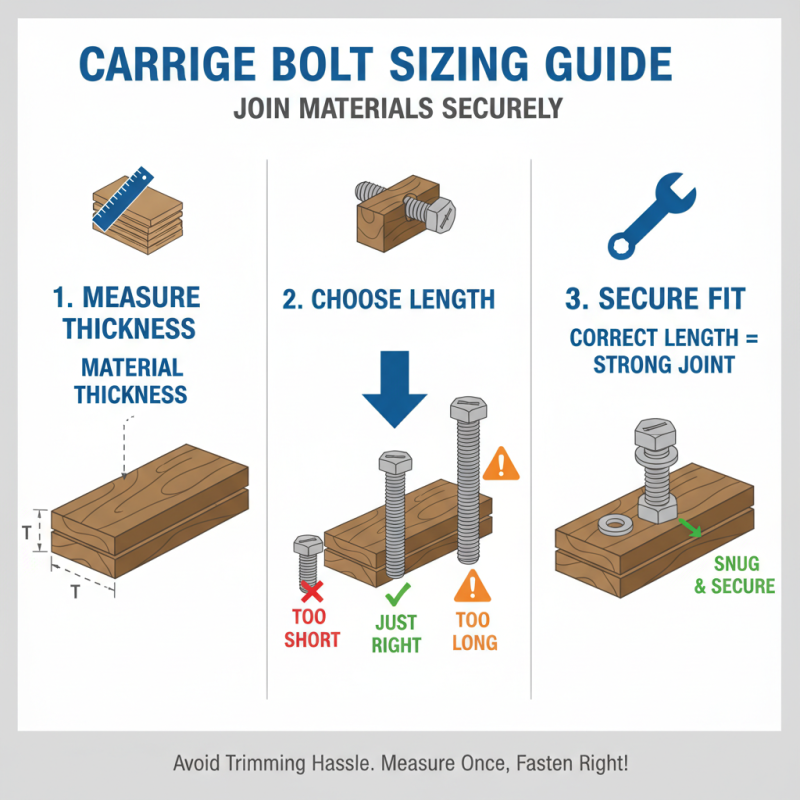

To use carriage bolts effectively, start by selecting the right size. This is crucial for ensuring proper fit and strength. Overly long bolts can weaken the structure. Short bolts may not provide enough grip. Always measure before you buy.

Another tip is to pre-drill your holes. It helps guide the bolt and reduce splitting in wood. However, do not drill too loosely; this can lead to wobble. If you're not careful, your project may end up needing a redo. A snug fit ensures durability.

Finally, consider using a washer under the nut. It helps distribute the load and prevents damage to the material.

Selecting the Right Size and Length for Your Project

When selecting the right size and length for your carriage bolts, start with the thickness of the materials you plan to join. Measure carefully, ensuring that the bolt extends through both pieces adequately. A bolt that is too short won’t provide a secure connection. Conversely, if it's too long, you may need to trim it, which can be a hassle.

Consider the diameter of the bolt as well. A thicker bolt offers more strength but can be overkill for lighter projects. Use a medium gauge for most applications. Don’t forget to account for the added length needed for the nut and washer if you’re using them. Sometimes, finding the perfect fit can be trial and error, especially if you’re working with non-standard materials.

Always ensure the bolt’s head fits into your design. A flat head may work better for some surfaces, while a round head could be necessary for others. It’s easy to underestimate these details, leading to fitting issues later. Reflect on your choices and possibly redraw your project specs. Getting the right size of carriage bolts is crucial for durability and safety in your build.

Preparing Materials and Pre-Drilling for Optimal Use

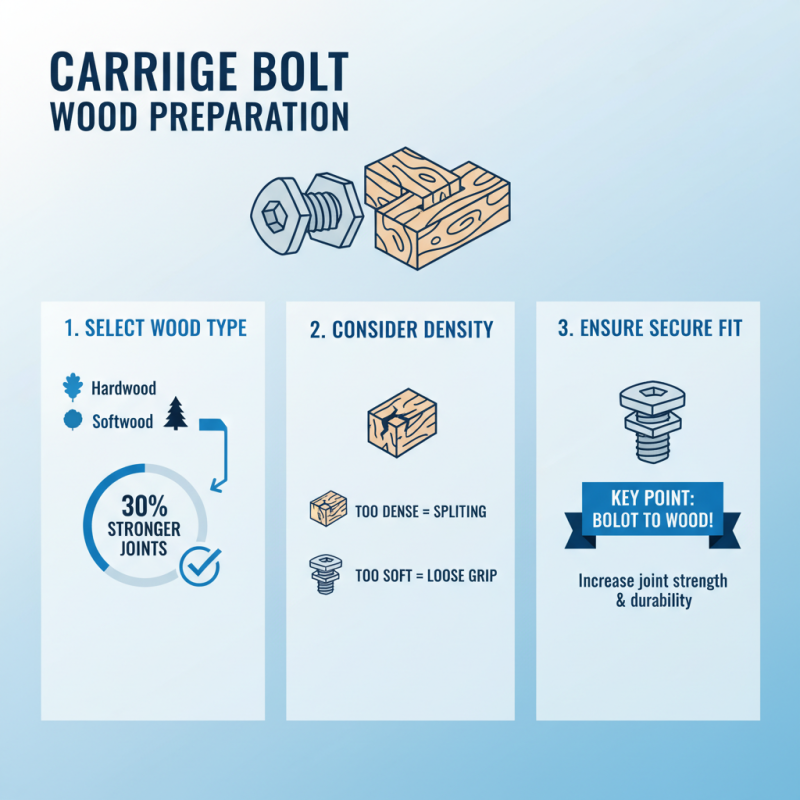

When using carriage bolts, preparing your materials is crucial. Begin by selecting the right materials, such as hardwood or softwood. According to industry reports, using suitable wood can increase joint strength by up to 30%. The wood type affects how the carriage bolt grips. If the wood is too dense, it may split. Conversely, if too soft, the bolt may not secure tightly.

Pre-drilling holes is often overlooked but vital. Experts recommend using a drill bit that matches the bolt's diameter. This step prevents wood from splitting during installation. A study showed that pre-drilled holes improve installation speed by 25%. Ensure the hole depth is slightly longer than the bolt's length. This helps avoid stress on the wood fibers.

For optimal results, consider the climate and wood conditions. Moisture content can alter the effectiveness of your setup. In dry conditions, wood can shrink, leading to loose bolts. In humid environments, wood swells, creating excess pressure on the bolt. Some users find themselves re-drilling and adjusting over time, questioning their methods. Even small miscalculations can lead to significant issues down the line.

Proper Techniques for Driving and Installing Carriage Bolts

Driving and installing carriage bolts requires some specific techniques to ensure a secure fit. Start by selecting the right size and length for your project. The bolt should extend past the surface it is fastening. This allows for proper threading and secure anchoring. It’s essential to drill the hole slightly larger than the bolt's diameter. This prevents wood from splitting and allows for easier installation.

When driving the bolt, always use a flat washer and a nut on the opposite side. The washer distributes the load and reduces the risk of damaging the material. Don't overtighten, as this could lead to stripping or breakage. Sometimes, you might find the bolt difficult to turn. Don't hesitate to back it out and adjust the fit. Realizing mistakes during installation is part of the process. It's wise to double-check your alignment before moving forward. You want everything to sit flush and secure. This way, your project will not only look polished but will also last longer.

Maintaining and Troubleshooting Common Issues with Carriage Bolts

Carriage bolts are widely used in woodworking and metal fastening. Regular maintenance can prevent common issues. One common problem is rust formation, especially in humid environments. Studies show that 40% of fastener failures relate to corrosion. To mitigate this, ensure you use a protective coating or regularly apply rust inhibitors.

Another issue is improper installation. Carriage bolts require a snug fit to function effectively. Reports indicate that over 30% of installation errors stem from misalignment. If installed improperly, they may loosen over time. Periodically check your hardware to ensure they remain tight. If you notice any wobbling or shifting, it’s a signal to address the installation immediately.

Inadequate load capacity can lead to failures as well. A weight that exceeds the specified limits can compromise the integrity of the joint. It’s crucial to understand load specifications. For instance, if a structural connection is overloaded consistently, it could lead to catastrophic failure. Reflect on these factors to enhance your application of carriage bolts effectively.

Related Posts

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

How to Choose High Tensile Carriage Bolt for Your Projects?

-

What is a Wood Screw and How to Choose the Right One for Your Project