Best High Tensile Carriage Bolt Applications and Benefits?

In the realm of construction and engineering, the significance of the High Tensile Carriage Bolt cannot be overstated. John Harper, a leading expert in structural integrity, once remarked, "High tensile carriage bolts enhance connection strength, making them essential for critical applications." These versatile fasteners are forged from high tensile steel, providing superior strength and resistance to fatigue.

High Tensile Carriage Bolts find extensive use in a variety of projects. They are commonly employed in heavy machinery, bridge construction, and furniture assembly. This versatility stems from their ability to withstand high loads and their corrosion resistance. However, there is a need for careful selection in their application. Not all projects require the same specifications, and using bolts that exceed project needs can lead to unnecessary costs.

Despite their advantages, challenges remain. Some users may overlook the importance of proper installation techniques. Misalignment can compromise the bolt's efficacy, leading to potential failures. Furthermore, regular inspections are crucial since the long-term performance of High Tensile Carriage Bolts can be influenced by environmental factors. Thus, a more mindful approach to their application could lead to improved outcomes in various industries.

Overview of High Tensile Carriage Bolts and Their Properties

High tensile carriage bolts are essential in various applications. They are designed to bear heavy loads and provide superior strength. These bolts possess a smooth, rounded head. This makes them easy to install and pretty effective in different projects. Their unique properties come from the high-strength steel used in production, ensuring durability and resistance to wear.

When working with high tensile carriage bolts, consider the material of the connected parts. Not all materials respond well to high tensile strength. Sometimes, mismatched materials can lead to failure. Always check compatibility. Additionally, pay attention to the environment. Exposure to moisture can cause rust. Coatings might offer extra protection.

Tips for tightening: Always start with hand-tightening. This will help you avoid overtightening. Use a torque wrench for precise tightening. This improves safety and functionality. Be cautious during installation. An uneven surface can lead to issues later. Proper installation ensures the effectiveness of these strong bolts.

Common Applications of High Tensile Carriage Bolts in Construction

High tensile carriage bolts are essential in construction. Their strength and durability make them ideal for various applications. These bolts often secure wooden structures, such as frames and decks. A common use is in beams, where they hold heavy loads. They provide stability, crucial for safety.

Another application is in metal connections. High tensile carriage bolts fasten steel components together. They withstand harsh conditions, contributing to longevity. Workers often face challenges when aligning bolts, leading to misaligned structures. Care in installation is important. Improperly placed bolts can result in weak joints.

These bolts are also used in bridges and scaffolding. Their high tensile strength ensures that they can bear considerable weight. Workers must regularly inspect them to prevent deterioration. Weather effects can be damaging. Regular checks can mitigate risks. High tensile carriage bolts are vital, but awareness of their maintenance is crucial.

Best High Tensile Carriage Bolt Applications and Benefits

| Application | Benefits | Material | Tensile Strength (MPa) |

|---|---|---|---|

| Bridges and Overpasses | High load capacity; corrosion resistance | Carbon Steel | 800 |

| Railway Construction | Durability; ease of installation | Stainless Steel | 700 |

| Heavy Machinery Assembly | Vibration resistance; reliability | Alloy Steel | 900 |

| Wood Structures | Aesthetic finish; maximum holding power | Galvanized Steel | 600 |

| Building Frames | Strength; versatile application | High-Strength Steel | 850 |

Advantages of Using High Tensile Carriage Bolts for Structural Integrity

High tensile carriage bolts are essential for various applications. They offer remarkable strength and durability, making them ideal for critical structural uses. These bolts resist shear forces effectively and can handle high loads without bending. Many industries benefit from using them, particularly in construction and manufacturing.

One key advantage of high tensile carriage bolts is their ability to maintain structural integrity. When installed correctly, they create robust connections that withstand environmental stresses. This reliability ensures safety, particularly in buildings and bridges. However, improper installation can lead to failure. Attention to detail during the installation process is crucial.

Moreover, high tensile carriage bolts help prevent issues like corrosion. They are often made from materials that resist environmental degradation. Still, it is vital to consider the surrounding conditions. For example, humidity and exposure to chemicals can shorten their lifespan. Selecting the right bolt for specific conditions should not be overlooked.

Maintenance and Installation Tips for High Tensile Carriage Bolts

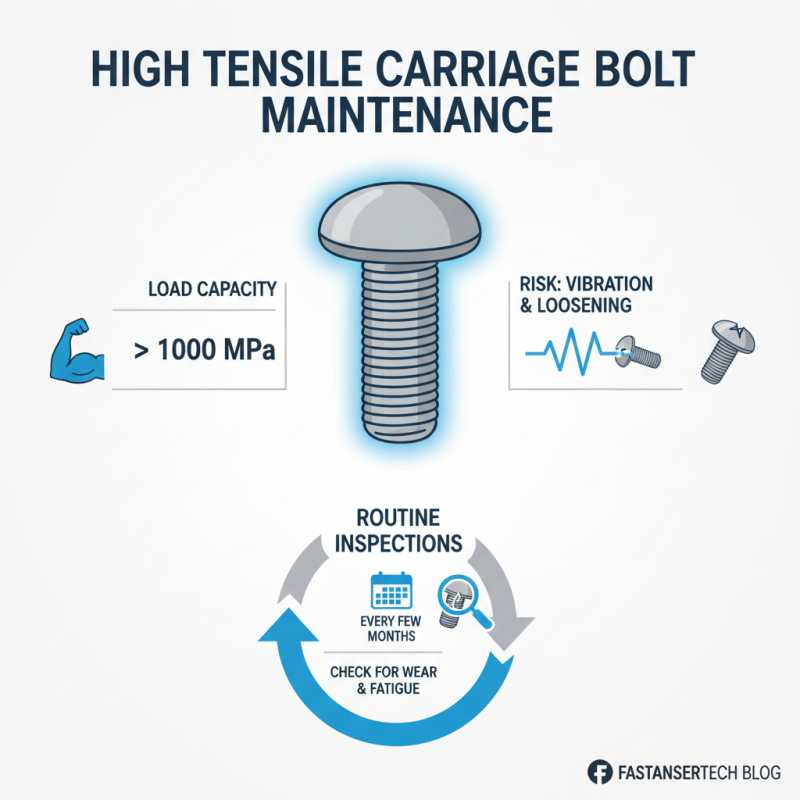

When installing high tensile carriage bolts, proper maintenance is essential for optimal performance. High tensile bolts are designed to handle significant loads, rated often above 1,000 MPa. However, without regular checks, fasteners can become loose over time, especially in high-vibration environments. Routine inspections every few months are recommended to identify any signs of wear or fatigue.

Installation should be approached with care. It's vital to ensure that the bolts are tightened to the specified torque settings. Inadequate torque can lead to joint failure. Furthermore, technique matters. Using a calibrated torque wrench ensures uniform distribution of force. One study indicated that improper installation could reduce bolt life by up to 30%.

Keep in mind that the material of the components being bolted also plays a role. Mismatching materials can lead to corrosion or mechanical degradation. Applying a suitable anti-seize lubricant during installation can help prevent these issues. However, over-lubrication should be avoided as it might impede the friction needed for proper tightening. Regular maintenance combined with meticulous installation practices ensures the longevity of high tensile carriage bolts in various applications.

Comparative Analysis: High Tensile vs. Standard Carriage Bolts

High tensile carriage bolts offer significant advantages over standard carriage bolts. Their tensile strength can reach up to 110,000 psi, compared to around 60,000 psi for standard options. This increased strength is vital in construction and heavy machinery applications where safety and durability are crucial. Using high tensile bolts can reduce the risk of failure in structural connections, making them ideal for high-stress environments.

Tips: Always check the load specifications before selecting a bolt type. High tensile bolts may cost more but ensure a more reliable and robust solution in demanding scenarios.

Corrosion resistance is another vital factor. High tensile bolts often feature better coatings for harsh environments. Standard bolts, while cheaper, may not withstand weathering as effectively. This leads to potential rust, weakening the join over time. Choosing the right material can save money on replacements. In many cases, investing in high tensile options pays off long-term with fewer maintenance needs.

Tips: Regularly inspect bolts in critical structures. A small crack can lead to big problems later. Don't overlook this essential step in maintenance.

Related Posts

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

Top 10 Square Neck Bolt Types You Need for Your Next Project

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Top Nut And Bolt Types for 2026 What You Need to Know?