What is a Stainless Wood Screw and How to Choose the Right One?

In the realm of construction and woodworking, the importance of choosing the right fasteners cannot be overstated. Stainless wood screws, known for their durability and resistance to corrosion, have become a staple in various applications, from outdoor furniture to structural projects. John Miller, a leading expert in woodworking fasteners, once stated, “Selecting the right stainless wood screw not only enhances the longevity of your project but also ensures structural integrity.” This highlights the critical nature of understanding the different types of stainless wood screws available in the market.

When it comes to choosing a stainless wood screw, various factors come into play, including material composition, size, and thread type. Each of these elements plays a vital role in the performance of the screw, affecting everything from ease of installation to the overall strength of the connection. Moreover, with a wide range of options available, it can often be daunting for both professionals and DIY enthusiasts to determine which stainless wood screw is best suited for their specific needs. In this article, we will explore the characteristics that define stainless wood screws, and provide guidance on how to make the right choice for any project.

What is a Stainless Wood Screw? Definition and Applications

A stainless wood screw is a fastener specifically designed for use in wooden structures, offering resistance to rust and corrosion. Made from stainless steel, these screws are not only durable but also enhance the longevity of wood products by maintaining structural integrity over time. The sleek finish of stainless steel adds an aesthetic appeal, making these screws a popular choice for both indoor and outdoor applications, including furniture assembly, decking, and cabinetry.

In terms of applications, stainless wood screws are particularly favored in environments where moisture exposure is common, such as outdoor projects or in coastal areas. Their resistance to tarnishing and staining ensures that wood remains visually appealing while providing the necessary strength for secure fastening. When choosing the right stainless wood screw, factors such as length, diameter, and thread design should be considered, depending on the specific requirements of your project. These screws are available in various head styles, allowing for versatility in use, whether for a concealed finish or increased grip.

Types of Stainless Steel Used in Wood Screws: Grades and Properties

When selecting a stainless wood screw, understanding the types of stainless steel used is crucial for ensuring optimal performance and longevity in various applications. The most common grades of stainless steel utilized in wood screws are 304 and 316. Grade 304 is known for its excellent corrosion resistance and is suitable for both indoor and outdoor use. According to a report by the American Institute of Steel Construction, 304 stainless steel exhibits about 80% of its original strength even after prolonged exposure to various environmental conditions.

On the other hand, grade 316 offers superior corrosion resistance, particularly in harsh marine environments or applications involving chemical exposure. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion. The National Association of Corrosion Engineers indicates that 316 stainless steel can withstand saline conditions better than any other steel grade. When choosing between these grades, it's essential to consider the specific environmental factors your project will encounter, as this choice directly impacts the durability of the screws and the overall integrity of the structure.

Factors to Consider When Choosing Stainless Wood Screws for Projects

When selecting stainless wood screws for your projects, several factors come into play to ensure that you make the right choice. One of the primary considerations is the type of stainless steel used. There are different grades, with 304 and 316 being the most common. Grade 304 is suitable for general outdoor use, while 316 offers enhanced corrosion resistance, making it ideal for marine environments or areas with higher exposure to moisture.

Another important factor is the screw size and length. It's crucial to match the screw length to the thickness of the materials you are working with to ensure a secure fit. Additionally, consider the screw head type; options like flat, pan, or hex heads can affect both functionality and aesthetics. Choosing the appropriate drive type, whether it's Philips, square, or hex, will also impact how easily the screws can be installed. Overall, carefully evaluating these factors will help you select the right stainless wood screws tailored to your specific needs.

Understanding Corrosion Resistance: Why Stainless Steel Matters in Wood Screws

When it comes to woodworking, the choice of screws can significantly impact the durability and functionality of your project. Stainless steel screws are renowned for their corrosion resistance, making them a preferred option for both indoor and outdoor applications. According to industry studies, stainless steel screws exhibit a highly impressive resistance to rust and pitting, even in harsh environments. Specifically, screws made from 304 stainless steel can withstand corrosion from moisture and chemicals, relevant for projects in coastal or humid areas. This property is vital, considering that corrosion can lead to structural failure over time, costing both time and resources.

While selecting stainless wood screws, it's important to consider factors like the environment in which they will be used. For instance, 316 stainless steel offers superior protection in marine applications due to its enhanced molybdenum content, which provides additional corrosion resistance. Additionally, the thread design and gauge of the screw can affect the holding power and shear strength. A report by the Fastener Quality Act indicates that correctly chosen screws can add to the integrity of wood fixtures significantly, preventing common issues like wood splitting and loosening over time.

Tips: Always assess the specific environmental conditions of your project to decide whether standard or marine-grade stainless steel screws are appropriate. Additionally, consider the length and thread type that will best serve your wooden materials, as this can prevent damage and ensure long-lasting results in your construction efforts.

What is a Stainless Wood Screw and How to Choose the Right One?

| Screw Type | Material | Corrosion Resistance | Best Uses | Diameter (inches) | Length (inches) |

|---|---|---|---|---|---|

| Wood Screw | Stainless Steel 304 | Good | Outdoor Furniture | #8 | 1.5 |

| Deck Screw | Stainless Steel 316 | Excellent | Decking Projects | #10 | 3 |

| Self-Tapping Screw | Stainless Steel 410 | Moderate | Metal to Wood Applications | #6 | 2 |

| Lag Screw | Stainless Steel Alloy | Very Good | Heavy-Duty Applications | 1/2 | 4 |

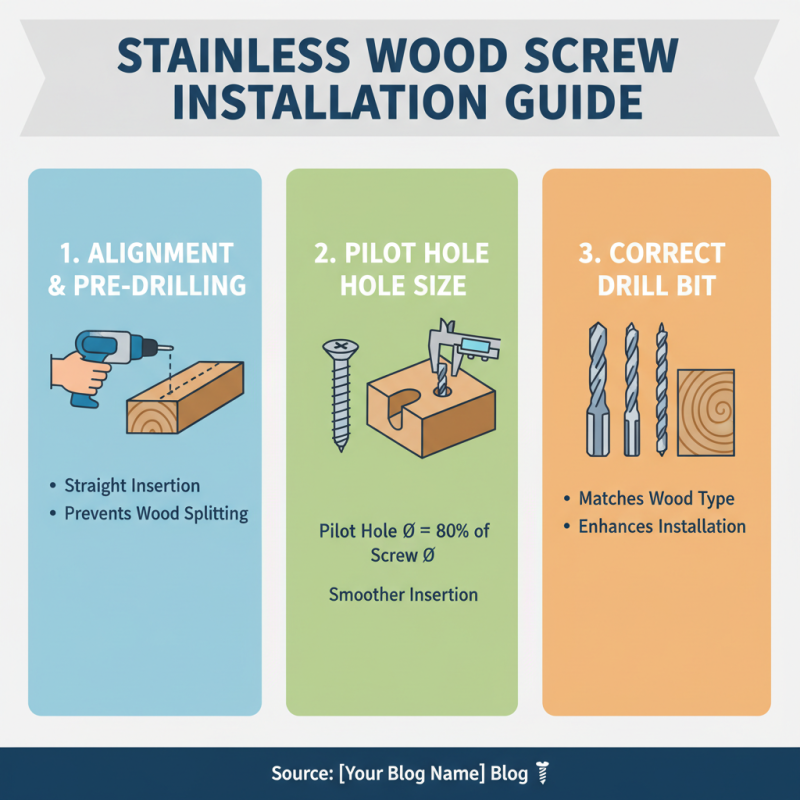

Guidelines for Proper Installation and Maintenance of Stainless Wood Screws

When installing stainless wood screws, it is crucial to ensure proper alignment and pre-drilling to prevent wood splitting. Pre-drilling creates a guide hole that allows for smoother insertion and reduces the risk of damaging the wood. The diameter of the pilot hole should ideally be 80% the size of the screw’s major diameter. Additionally, using the right drill bit for the type of wood and the specific screw size can greatly enhance the installation process.

Proper maintenance of stainless wood screws primarily involves regular inspections to check for corrosion or loosening. Although stainless steel is resistant to rust, it can still be affected by certain environmental conditions, particularly in coastal areas or places with high humidity. Applying a protective sealant or coating can prolong the lifespan of the screws. Furthermore, during maintenance, it is advisable to tighten any loose screws gently, as overtightening can lead to damage. Keeping the surrounding area clean and free of debris will also help maintain the integrity and functionality of the screws over time.