Top Nut And Bolt Types for 2026 What You Need to Know?

As we approach 2026, understanding the evolving landscape of the nut and bolt industry is crucial. The global market for nuts and bolts is projected to grow significantly, with estimates from industry reports suggesting an increase of over 5% annually. This growth reflects advancements in manufacturing and material science. According to expert James Harrington, "The future of nut and bolt technology lies in innovation and sustainability."

In recent years, the demand for specialized fasteners has surged. Industries such as automotive and aerospace drive this change, requiring stronger and lighter materials. However, this rapid transformation also leads to challenges. Companies must navigate compliance with stricter regulations and shifting customer preferences. Product differentiation becomes essential in a crowded market.

Despite this promise, flaws in existing designs must be addressed. Some manufacturers still rely on outdated processes, leading to inconsistencies in quality. As the industry evolves, a focus on precision and reliability remains paramount. Balancing innovation with these foundational aspects can define success in the competitive nut and bolt sector.

Top Nut and Bolt Types Commonly Used in Various Industries

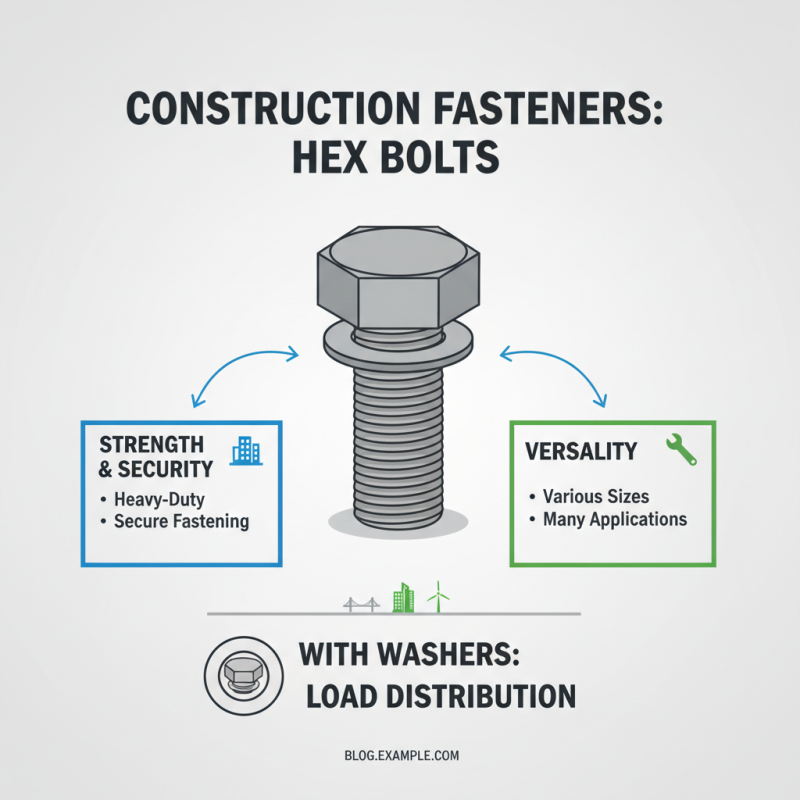

In various industries, the choice of nuts and bolts can be crucial. Different projects demand specific types. For instance, construction often relies on hex bolts for their strength. These bolts provide secure fastening in heavy-duty applications. They come in various sizes, making them versatile for many tasks. Moreover, washers are frequently used with these bolts to distribute load.

In the automotive sector, flange nuts are quite popular. They have a built-in washer that helps prevent loosening. This design is essential for vehicles that endure vibrations. However, one must choose the right size for optimal performance. Wrong-sized fasteners can lead to failures and costly repairs. Also, keep in mind that not all nuts are suitable for every bolt type. Compatibility is key to achieving a secure fit.

Aerospace applications often utilize lock nuts. They prevent loosening under extreme conditions. Such environments can be unpredictable. This makes reliability non-negotiable. Still, using these nuts demands careful consideration. If a lock nut is installed incorrectly, it can compromise safety. Unforeseen consequences may arise from seemingly trivial mistakes in assembly. Thus, understanding your materials is vital.

Key Features and Benefits of Each Nut and Bolt Type

When exploring nuts and bolts for 2026, it's essential to understand the key features and benefits of various types. For example, hex nuts are widely used due to their versatility. They provide excellent grip and are easy to tighten. These nuts work well with many bolt types, making them a reliable choice for many projects.

Another popular type is the lock nut. Lock nuts prevent loosening under vibration, which is crucial in dynamic applications. If a project involves machinery or vehicles, these can be a lifesaver. Their design often includes nylon inserts or serrated faces to enhance grip. However, some users might overlook the importance of torque specifications when using them.

Finally, there are flange bolts with a wide bearing surface. These bolts distribute loads effectively, reducing the risk of damage to materials. They're beneficial in structural applications where strength is vital. In some cases, though, users may choose a smaller size thinking it’s sufficient, which can lead to failures. Understanding the proper application of each type can make all the difference.

Top Nut And Bolt Types for 2026 - Key Features and Benefits

| Nut/Bolt Type | Key Features | Benefits |

|---|---|---|

| Hex Nuts | Standard six-sided shape, easy to tighten with tools. | Widely used and compatible with many tools, providing reliability. |

| Lock Nuts | Designed to resist loosening under vibration. | Enhanced security and stability in critical applications. |

| Machine Screws | Cylindrical head, uniform diameter. | Ideal for fastening into pre-tapped holes, high precision. |

| Carriage Bolts | Rounded head with a square neck to prevent rotation. | Great for wood applications, providing a clean finish. |

| Cap Screws | Hexagonal head, designed for high strength applications. | Superior strength, suitable for heavy-duty applications. |

| Wing Nuts | Easily adjustable by hand thanks to wing-like projections. | Quick installation and removal without tools, convenient in tight spaces. |

| Eyebolts | Looped head for connecting items through a central point. | Ideal for lifting and securing applications, providing versatility. |

Emerging Trends in Nut and Bolt Technology for 2026

The nut and bolt industry is evolving rapidly. In 2026, a few key trends will reshape the landscape. Emerging technologies are making these fasteners more reliable and efficient. For instance, the introduction of advanced materials can increase strength while reducing weight. This shift may enhance overall performance in various applications.

According to a recent market report, about 30% of manufacturers are expected to adopt smart fastening technology by 2026. These fasteners could integrate sensors to provide real-time performance data. Such innovations can lead to improved maintenance and safety. However, not every company is prepared for this change. Some may struggle to adapt to these new technologies quickly.

Sustainability is another growing focus. More companies are looking for eco-friendly materials in their products. Reports suggest that the demand for recycled metals in fasteners could rise by 25% in the coming years. While this is a positive trend, not all manufacturers have developed effective recycling processes yet. There is a risk that they might fall behind in this critical aspect of production.

Top Nut And Bolt Types for 2026

This chart illustrates the percentage share of various nut and bolt types expected to dominate the market in 2026. The data reflects emerging trends in nut and bolt technology, highlighting their applications in various industries.

Selecting the Right Nut and Bolt for Specific Applications

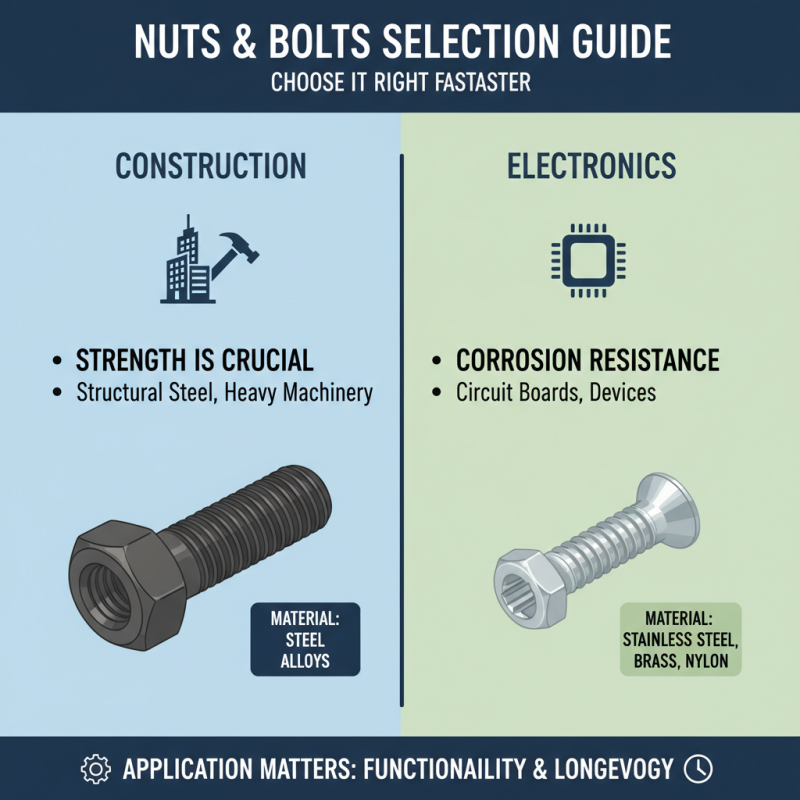

When selecting nuts and bolts, consider your specific application. Different industries use various materials and designs. For construction, strength is crucial. For electronics, look for corrosion resistance. The right type can impact functionality and longevity.

**Tips**: Always match the nut and bolt sizes precisely. A small mismatch can lead to failures. Also, consider the environmental factors. If parts will face humidity, choose stainless steel or coated options. This protects against rust.

Surface finish also plays a role. Some projects may require a smooth finish for better aesthetics. Others might need a rough texture for grip. Think carefully about how each factor aligns with your goals. Mistakes can lead to rework and wasted resources. Choose wisely to ensure durability and safety.

Maintenance and Best Practices for Nut and Bolt Use

Proper maintenance of nuts and bolts is crucial for ensuring

structural integrity. Regular inspections can prevent failures. According to recent industry reports, around

30% of structural failures are linked to inadequate bolt maintenance.

Inspecting these fasteners every few months can help identify wear or corrosion. Simple visual checks are effective.

Look for signs of rust or deformation. Remember, small issues can lead to

significant problems.

Using the correct torque settings is essential too. Over-tightening

can cause bolts to break. A torque range of 60-80% of the bolt's yield strength

is often recommended. Using a calibrated torque wrench is vital. Reports suggest that vital machinery failures

often stem from improper torque. Always document torque settings during assembly. This practice may seem tedious but is important.

Greasing or using anti-seize compounds can enhance longevity. These products reduce friction and prevent galling.

However, not all applications require lubrication. Assess the environment. Moisture

and extreme temperatures can affect these decisions. Understanding your materials and their uses can prevent costly mistakes.

Relying solely on recommendations may lead to issues. Exploring your specific needs can lead to better outcomes.

Related Posts

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

10 Best Furniture Fasteners for Durable and Reliable Assembly

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

How to Choose the Right Furniture Screw for Your DIY Projects

-

Top 2025 Furniture Screw Types: Which One is Right for Your Project?