Top 10 Square Neck Bolt Types You Need for Your Next Project

In the world of construction and manufacturing, the choice of fasteners can significantly affect the durability and functionality of a project. One type that stands out for its versatility and strength is the Square Neck Bolt. According to renowned industry expert, Dr. Emily Harper, "The Square Neck Bolt is more than just a fastener; it's a fundamental component that can enhance the structural integrity of various assemblies." This statement encapsulates the essence of why understanding the different types of Square Neck Bolts is crucial for engineers and builders alike.

As projects become more complex, the demand for reliable fastening solutions increases. Selecting the right Square Neck Bolt can lead to optimal performance and longevity, making it essential for professionals to be knowledgeable about their options. From construction to automotive applications, Square Neck Bolts offer unique advantages, including resistance to slippage and improved load distribution.

In this article, we will explore the top 10 square neck bolt types that you should consider for your next project. By understanding the distinct characteristics and applications of these fasteners, you can make informed decisions that will ultimately contribute to the success of your endeavors.

Types of Square Neck Bolts: An Overview of Material Composition

When selecting square neck bolts for various applications, understanding their material composition is essential for ensuring optimal performance and durability. Square neck bolts are primarily composed of steel, stainless steel, and aluminum, each offering distinct benefits suited to different environments and load requirements. For instance, carbon steel bolts, particularly those with heat-treated properties, can achieve tensile strengths exceeding 1,000 MPa, making them ideal for heavy-duty applications in construction and manufacturing settings.

Stainless steel square neck bolts, often specified for their corrosion resistance, are classified into different grades, notably 304 and 316. According to industry reports, grade 316 stainless steel contains molybdenum, providing increased resistance to pitting in chloride environments, which is critical in marine and chemical processing uses. Moreover, aluminum square neck bolts, while lighter, should be chosen for applications where weight savings are crucial without compromising structural integrity. Reports indicate that aluminum bolts can effectively withstand tensile loads of up to 370 MPa, making them suitable for automotive and aerospace components where performance and weight are paramount.

Each material type not only affects the mechanical properties of the bolt but also influences factors such as cost, machinability, and overall lifecycle performance. Data from the Fastener Technology International suggests that selecting the right material according to specific project needs can reduce long-term maintenance costs and enhance the reliability of the assembly, thereby underscoring the importance of informed material choices in bolt selection.

Top 10 Square Neck Bolt Types You Need for Your Next Project

Understanding the Load-Bearing Capacities of Square Neck Bolts

When selecting square neck bolts for your project, understanding their load-bearing capacities is crucial for ensuring structural integrity and safety. Square neck bolts are unique in design, featuring a square-shaped neck that helps prevent rotation when they are installed. This design can be particularly advantageous in applications where torque needs to be precisely controlled. The load-bearing capacity of these bolts is influenced by factors such as material type, bolt diameter, and the grade of the bolt. For instance, higher-grade bolts tend to withstand greater loads, making them ideal for heavy-duty applications.

Tips: Always consult the manufacturer's specifications for load ratings, and consider the environmental conditions your project may encounter. Corrosion resistance may also be a vital factor if the bolts are used outdoors or in harsh environments. Additionally, ensure that the bolts are properly installed with the correct torque settings to maximize their load-bearing capabilities.

When planning your project, don't overlook the importance of conducting a thorough analysis of the anticipated load. Factors such as dynamic loading conditions, potential shock loads, and fatigue over time can impact overall performance. Using software for finite element analysis or consulting an engineer may be beneficial in accurately assessing load requirements and choosing the most suitable square neck bolt type for your specific application. This diligence can save time and resources in the long run.

Common Applications of Square Neck Bolts in Construction and Manufacturing

Square neck bolts are a critical component in various construction and manufacturing applications due to their unique design that provides enhanced stability and resistance to rotation. This bolt type is particularly favored where strong clamping force is essential, such as in structural connections and assembly operations. According to the Fastener Industry Study, the demand for square neck bolts is projected to grow significantly, driven by their ability to improve load distribution and minimize loosening under dynamic loads.

In the construction sector, square neck bolts are often used in fabricating steel frames and securing beams to columns, as their square neck prevents the bolt from turning when tightened. This feature is vital in ensuring the structural integrity of buildings and bridges, where the reliability of fasteners is crucial. Similarly, in manufacturing, square neck bolts play a significant role in heavy machinery assembly, providing robust connections that can withstand the harsh conditions often present in industrial environments. A report from the International Fasteners Association highlights that approximately 25% of all fastener-related failures are attributed to improper fastening techniques, emphasizing the importance of using the right type of fastener, such as square neck bolts, to enhance safety and performance.

Top 10 Square Neck Bolt Types You Need for Your Next Project

| Bolt Type | Material | Size (mm) | Common Applications |

|---|---|---|---|

| Standard Square Neck Bolt | Steel | M6 | General construction, Machinery assembly |

| Heavy-Duty Square Neck Bolt | High-Strength Steel | M8 | Structural applications, Heavy machinery |

| Corrosion-Resistant Square Neck Bolt | Stainless Steel | M10 | Outdoor structures, Marine applications |

| Square Neck Anchor Bolt | Steel with Coating | M12 | Foundation anchoring, Concrete applications |

| Square Neck Carriage Bolt | Steel | M16 | Wood-to-wood connections, Flooring |

| Square Neck Flanged Bolt | Alloy Steel | M20 | Automotive assembly, Machinery |

| Square Neck Lag Bolt | Carbon Steel | M24 | Construction, Decking |

| Tension Control Square Neck Bolt | High-Strength Steel | M30 | Pre-engineered structures, Steel construction |

| Square Neck Shoulder Bolt | Stainless Steel | M36 | Custom manufacturing, Machine parts |

| Square Neck Machine Bolt | Alloy Steel | M42 | Heavy machinery, Industrial equipment |

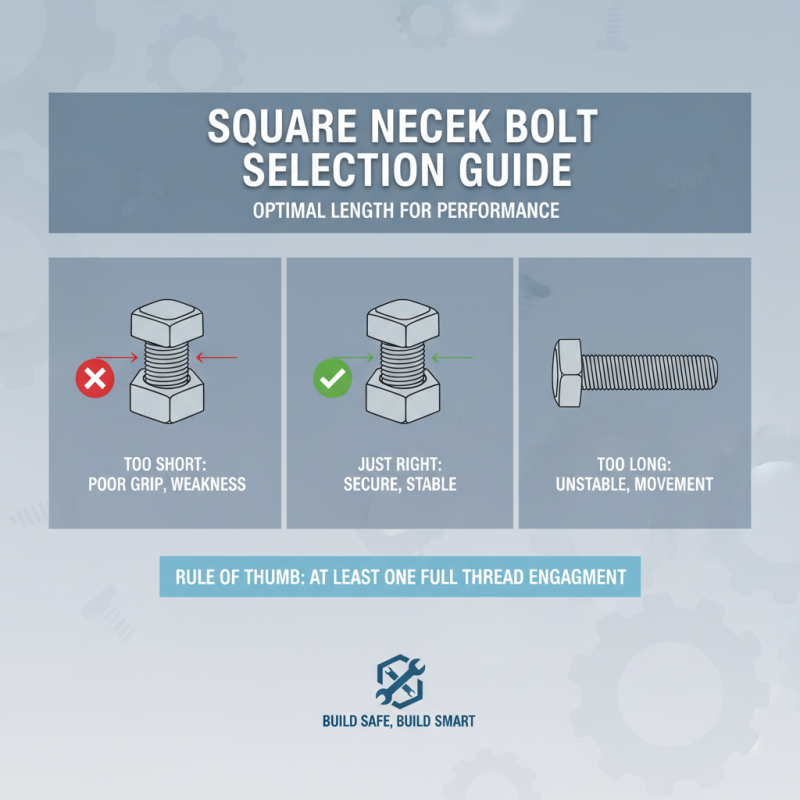

Choosing the Right Square Neck Bolt Length for Optimal Performance

When selecting the appropriate square neck bolt for your next project, the length of the bolt plays a crucial role in ensuring optimal performance. A bolt that is too short may not provide the necessary grip, while one that is excessively long can lead to structural weaknesses and unwanted movement. To determine the right length, consider the materials you are fastening and the thickness of the components involved. A general rule of thumb is to allow for at least one full thread engagement in the nut or the material being fastened.

Tips for choosing the right square neck bolt length include measuring the combined thickness of the materials being connected and allowing for additional length when washers or spacers are used. It's also essential to factor in any potential expansion or contraction of materials due to temperature fluctuations. Properly sizing your bolts can help prevent failures, ensuring that your assembly remains robust and reliable.

Additionally, consider utilizing a bolt length calculator or reference chart specific to your application to make informed decisions. This can simplify the process and help you avoid common mistakes that might result in using the wrong size. The right length not only enhances the strength of your connection but also contributes to the overall efficiency and longevity of your project.

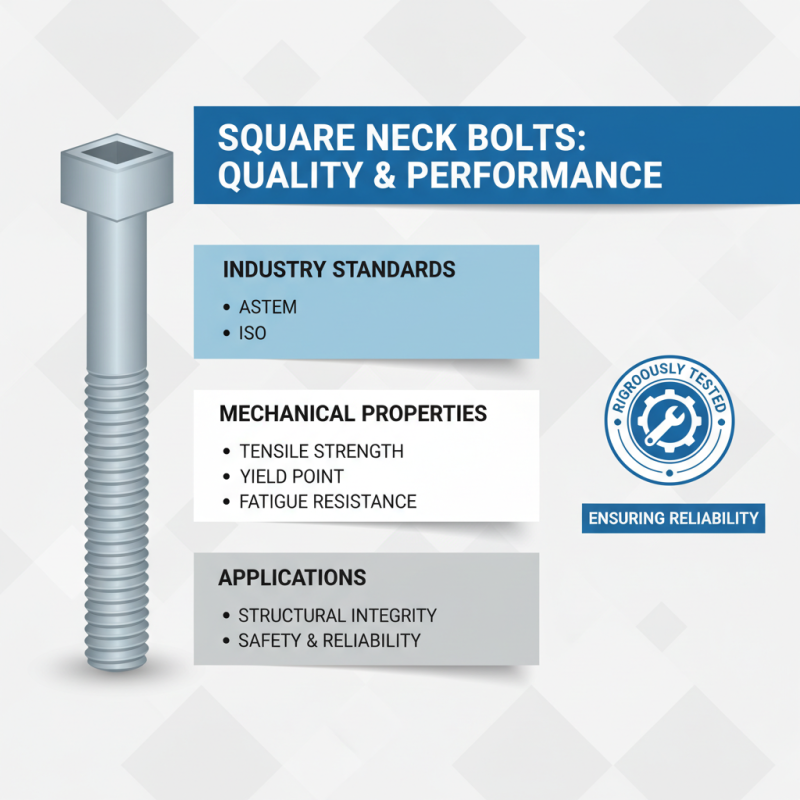

Industry Standards and Specifications for Square Neck Bolt Quality

When selecting square neck bolts for a project, it’s essential to adhere to industry standards and specifications that ensure quality and performance. These bolts are often subject to rigorous testing to meet mechanical properties, such as tensile strength, yield point, and fatigue resistance, as outlined in various standards like ASTM and ISO. Understanding these specifications helps engineers and designers select the right bolt for their application, ensuring safety and reliability in structural integrity.

Additionally, surface treatment and material composition are critical factors influencing the quality of square neck bolts. Common materials include carbon steel, stainless steel, and alloyed metals, each with specific corrosion resistance and load-bearing capabilities. Each bolt type should be evaluated for its finish, whether it’s zinc-plated for enhanced protection against rust or left untreated for specific applications. By following these industry guidelines, projects can achieve optimal durability and effectiveness, ultimately leading to successful implementation and longevity of the constructions involved.

Related Posts

-

How to Choose the Right Furniture Screw for Your DIY Projects

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

What is a Stainless Wood Screw and How to Choose the Right One?