Top 10 Stainless Carriage Bolt Options for Your Next Project

In the world of construction and craftsmanship, the choice of fasteners can significantly impact the durability and longevity of a project. Among these essential components, the Stainless Carriage Bolt stands out due to its unique design and robust properties. Industry expert Mark Johnson, a veteran in the fasteners sector, emphasizes the importance of quality in fastening solutions: "Choosing the right stainless carriage bolt can make all the difference in ensuring the integrity of your structure."

Stainless carriage bolts are not only resistant to rust and corrosion, but they also provide a sleek finish that is aesthetically pleasing in applications where they are visible. Their rounded head and square neck ensure a secure fit and prevent bolt rotation during installation, making them a preferred choice for both professionals and DIY enthusiasts alike. As we delve into the top 10 stainless carriage bolt options for your next project, it's crucial to consider the specific requirements of your application and the advantages that stainless steel brings to the table. By equipping yourself with the right information, you can elevate the quality of your work and achieve lasting results.

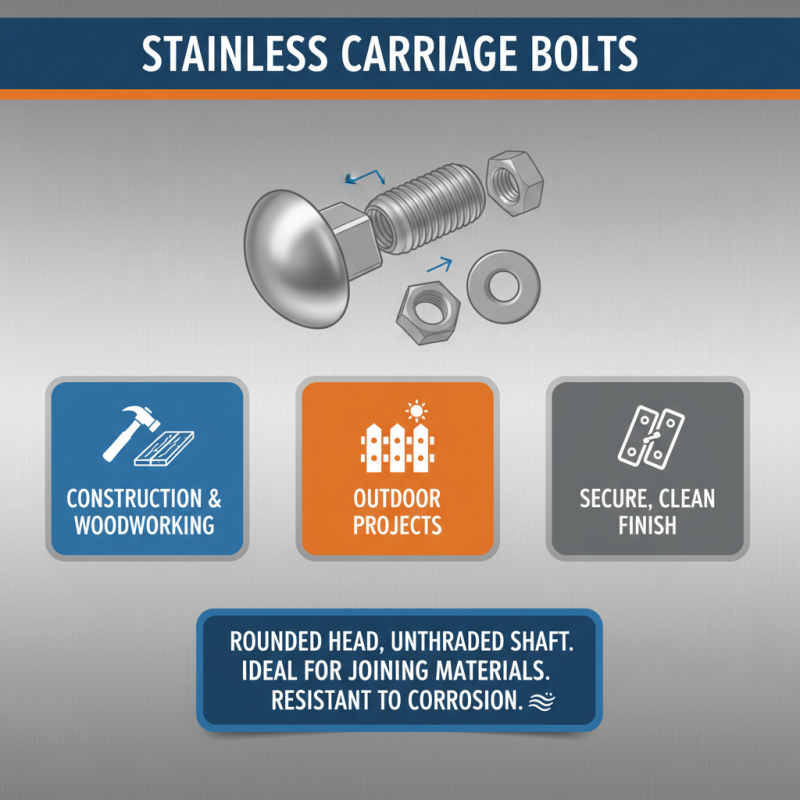

Understanding Stainless Carriage Bolts: Definition and Features

Stainless carriage bolts are vital fasteners commonly used in construction, woodworking, and outdoor projects. Defined as a type of bolt with a rounded head and a smooth, unthreaded shaft, they are designed for use in applications where the bolt must be secured against a surface. These bolts are often used in conjunction with a nut and washer to provide maximum strength and stability. Their unique design allows them to fit snugly into pre-drilled holes, making them ideal for joining two pieces of material together, especially when a clean look is desired.

One of the standout features of stainless carriage bolts is their corrosion resistance. According to a report by the American Institute of Steel Construction, stainless steel fasteners can offer protection in harsh environments, particularly in coastal or high-humidity areas where regular steel would rust and fail. This makes stainless carriage bolts suitable for both indoor and outdoor applications, providing longevity and durable performance.

Tip: When selecting stainless carriage bolts for your next project, consider the grade of stainless steel. Higher grades, such as 316, provide better resistance to corrosion in saltwater environments, while 304 grade is suitable for general use. Additionally, ensure that you use a washer under the nut to distribute the load and prevent damage to the material being fastened. Depending on your project requirements, measuring the length and diameter of the bolt accurately can lead to the right fit and enhance the structural integrity of your assembly.

Key Factors to Consider When Choosing Stainless Carriage Bolts

When selecting stainless carriage bolts for your next project, several key factors come into play to ensure you make the right choice. First and foremost, consider the grade of stainless steel. Different grades offer varying levels of corrosion resistance and strength. For outdoor projects or applications exposed to moisture, opting for higher-grade stainless steel, such as 316, can provide excellent durability against rust and environmental factors.

Another important factor is the length and diameter of the bolts. You need to assess the materials you are fastening together and the weight they will bear. It's essential to choose bolts that are long enough to provide a secure fit while ensuring their diameter aligns with the size of the pre-drilled holes for optimal performance. Additionally, the head style of the bolt should match the aesthetic and functional requirements of your project. Whether you need a flat head or a rounded finish, selecting the right type will not only affect the bolt’s performance but also the overall appearance of the final assembly.

Top 10 Stainless Carriage Bolt Options for Diverse Applications

When it comes to choosing the right fasteners for various projects, stainless carriage bolts are an excellent choice due to their durability and resistance to corrosion. According to the Fastener Quality Act, stainless steel fasteners, including carriage bolts, account for an increasing share of the market, driven by their applicability in diverse environments, from marine and automotive to construction and outdoor furniture. The demand for stainless carriage bolts has surged, with the global fasteners market expected to grow at a CAGR of 4.5%, reaching $93 billion by 2026. This growth highlights the importance of selecting high-quality bolts that can withstand harsh conditions and maintain structural integrity.

Stainless carriage bolts come in various sizes and grades, making them suitable for a wide range of applications. For instance, they are ideal for use in projects requiring a robust fastening solution, such as securing wooden structures or metal components in demanding situations. Their design, featuring a smooth rounded head and a square neck, prevents the bolt from rotating in the pre-drilled hole, ensuring a secure fit. The versatility of stainless carriage bolts makes them essential for both DIY enthusiasts and professional contractors alike, particularly as sustainability becomes a priority; stainless steel is highly recyclable, contributing to environmentally friendly practices in construction and manufacturing.

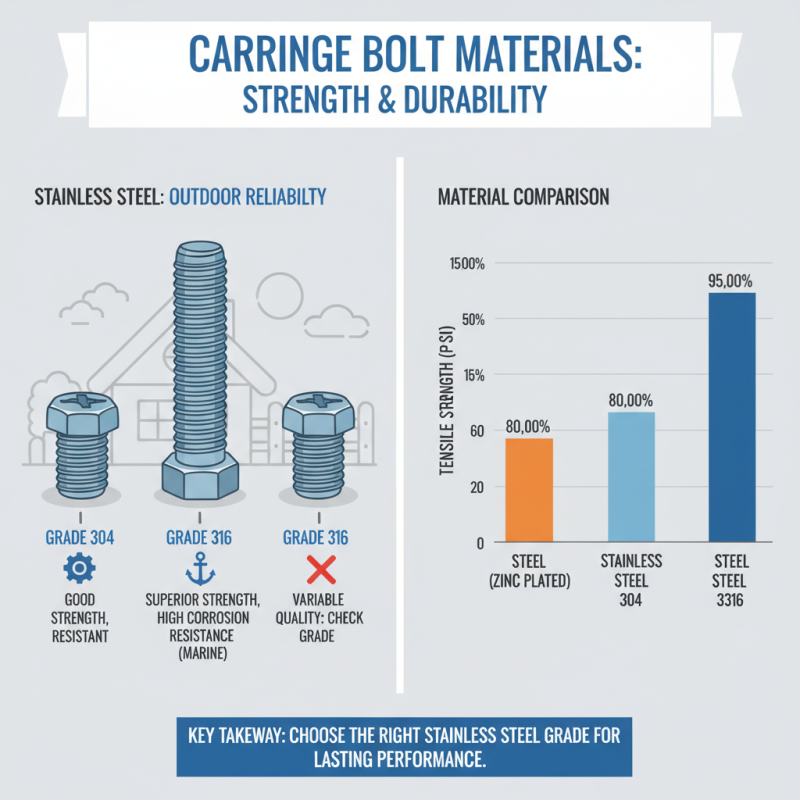

Comparative Analysis of Strength and Durability in Bolt Materials

When selecting carriage bolts for your next project, understanding the strength and durability of various materials is critical. Stainless steel is a popular choice due to its excellent resistance to corrosion and rust, making it ideal for outdoor applications. The inherent strength of stainless steel provides satisfactory performance under load, ensuring long-term reliability in various environments. However, the quality of stainless steel can vary. For example, different grades offer distinct tensile strengths, such as 304 and 316 stainless, which are standardized classifications for durability against mechanical stress and environmental factors.

In addition to stainless steel, other materials such as carbon steel also deserve consideration for different applications. While carbon steel bolts can provide high strength and are often less expensive than their stainless counterparts, they usually require protective coatings to prevent rusting, which may affect their long-term durability in moist conditions. A comparative analysis reveals that while stainless steel is favored for its resistant properties, carbon steel can still be a viable option when used in dry environments or when cost efficiency is essential. Ultimately, evaluating the specific requirements of your project, including load-bearing capacity and environmental exposure, will inform the best material choice for carriage bolts.

Best Practices for Installing Stainless Carriage Bolts in Your Projects

When it comes to installing stainless carriage bolts in your projects, following best practices is essential for ensuring durability and reliability. First, always start by selecting the appropriate size and length of the carriage bolt suited for your specific application. This consideration helps in achieving a secure fit and optimal load-bearing capacity. Additionally, it's crucial to use the correct tools for installation, such as a properly sized wrench or socket, to avoid damaging the bolt's head or threading during the tightening process.

Another best practice is to pre-drill holes in the materials you plan to join. This prevents wood from splitting and ensures that the bolts enter cleanly and securely. When inserting the carriage bolts, utilize washers to distribute the load evenly across the surface and to prevent wear on the material. Tightening should be done gradually and evenly to avoid any misalignment or undue stress on the components being fastened. Finally, consider applying a thread-locking adhesive to add an extra layer of security, particularly in environments subject to vibration or movement. Following these guidelines will help ensure that your project not only looks great but also stands the test of time.

Top 10 Stainless Carriage Bolt Options for Your Next Project

| Bolt Size | Length (inches) | Diameter (inches) | Material Grade | Corrosion Resistance | Typical Uses |

|---|---|---|---|---|---|

| 1/4" x 1" | 1 | 0.25 | A2 | Moderate | Wood applications |

| 5/16" x 2" | 2 | 0.31 | A4 | High | Marine applications |

| 3/8" x 1.5" | 1.5 | 0.375 | A2 | Moderate | Furniture assembly |

| 1/2" x 3" | 3 | 0.5 | A4 | High | Outdoor structures |

| 3/8" x 2" | 2 | 0.375 | A4 | High | Brackets and hangers |

| 1/4" x 3/4" | 0.75 | 0.25 | A2 | Moderate | DIY projects |

| 5/16" x 1 1/4" | 1.25 | 0.31 | A2 | Moderate | General applications |

| 1/2" x 4" | 4 | 0.5 | A4 | High | Heavy-duty construction |

| 5/8" x 5" | 5 | 0.625 | A4 | High | Industrial use |

| 3/8" x 4" | 4 | 0.375 | A2 | Moderate | Metal and wood connection |

Related Posts

-

Top 2025 Furniture Screw Types: Which One is Right for Your Project?

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Best High Tensile Carriage Bolts for Strength and Durability You Need to Know

-

What is a Wood Screw and How to Choose the Right One for Your Project

-

What is a Stainless Wood Screw and How to Choose the Right One?

-

Why You Need High Quality Carriage Bolts for Your DIY Projects