Top 10 Types of Furniture Fasteners You Need to Know?

Furniture fasteners play a crucial role in the assembly and stability of various furniture pieces. These small yet essential components often go unnoticed, but they significantly impact the durability of our furniture. Choosing the right furniture fastener can improve the quality of your items and enhance their lifespan.

There are many types of furniture fasteners available. Some are simple, while others are more complex. Each type serves a specific purpose, and understanding these can aid in effective furniture assembly. For example, screws are widely used, but dowels offer a different solution for joints. Knowing the differences can help in choosing wisely.

While it may seem easy to select fasteners, mistakes can happen. An inadequate fastener can lead to instability. This may compromise the entire furniture structure. Reflecting on the importance of these components is necessary to avoid mishaps. Ultimately, knowing about furniture fasteners is key to successful woodworking and assembly projects.

Types of Furniture Fasteners: An Overview of Essential Options

When it comes to furniture construction, understanding fasteners is crucial. There are various types available, each serving a unique purpose and fitting specific styles. Wood screws are popular for assembling wooden furniture. They grip tightly and offer good stability. However, they can strip if over-tightened, leading to issues.

Dowels provide a seamless look and are often used in cabinets. They fit snugly into drilled holes, providing strength. Yet, they require precision. Misaligned holes can create weaknesses. Fastener systems like cam locks are functional but sometimes challenging to maneuver. They require careful handling to avoid breakage.

Finally, you might consider brackets and corner braces. They enhance stability, especially in heavy furniture, but may be visible.

It’s important to choose wisely. Not all fasteners suit every project. Reflect on the purpose and load of your furniture. Selecting the right fastener can save time and resources.

Understanding Screws: The Cornerstone of Furniture Assembly

Screws are fundamental to furniture assembly. They provide stability and strength. Without them, many items would fall apart. Knowing the right screws can make a big difference.

When selecting screws, consider their length and width. Proper sizing ensures a snug fit. Too long, and you risk damaging the furniture. Too short, and the assembly might weaken. Pay attention to the material as well. Stainless steel screws resist rusting, making them ideal for various climates. Wooden screws should have sharp points for easy driving.

Tip: Always pre-drill holes when working with hardwood. It prevents splitting and makes insertion easier. Additionally, don’t over-tighten screws. This can strip the hole, leading to a wobbly structure.

Understanding screw types is essential. Flat-head screws sit flush against surfaces. They are perfect for a clean look. Round-head screws, on the other hand, stand out and add character. Choose the right type based on your aesthetic preference and functionality needs. Remember, every choice impacts the overall durability of the furniture.

Top 10 Types of Furniture Fasteners You Need to Know

Exploring Dowels: Strength and Stability in Furniture Construction

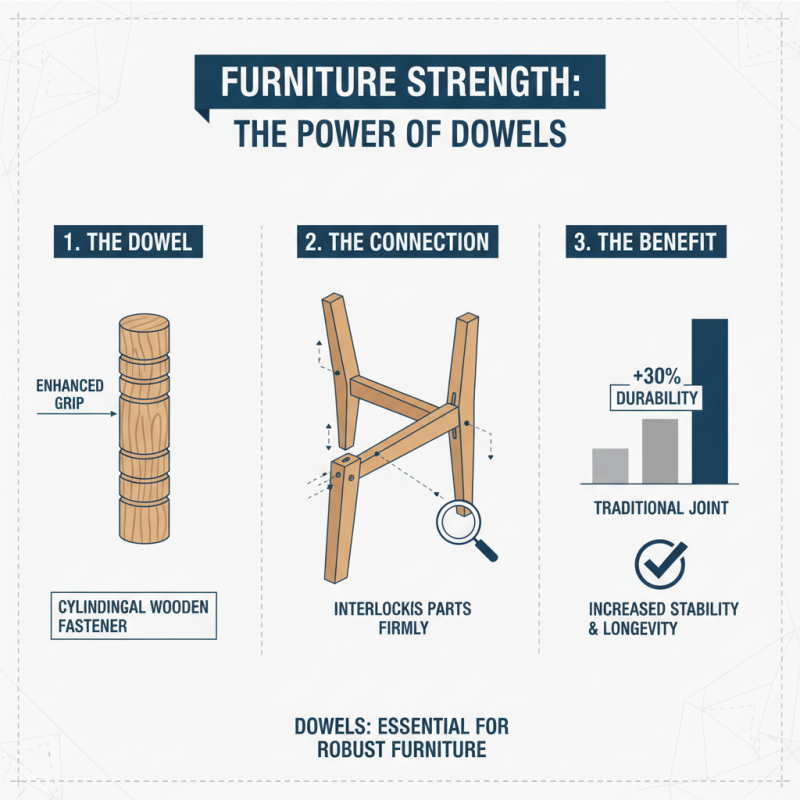

Dowels are key elements in furniture construction. These cylindrical wooden pieces provide strength and stability. They interlock two furniture parts, ensuring they hold together firmly. According to industry reports, properly placed dowels can enhance furniture durability by up to 30%. This makes them a preferred choice for many builders.

Using dowels isn’t always straightforward. The precision in drilling holes is crucial. Misalignment can weaken the bond. It's essential to pay attention. Many novice builders make the mistake of rushing this process. This often leads to subpar stability and early wear.

Tip: Always measure twice before drilling. This can save time and resources. A dowel’s effectiveness relies heavily on accuracy. Ensure a snug fit for optimal strength.

When considering dowels, realize that material matters. Hardwood dowels typically offer better strength than softwood. However, the choice of materials can complicate construction. You may need different tools and techniques. This can lead to potential errors. Assess your skills before diving into advanced projects.

Tip: Don’t hesitate to practice on scrap wood. This is where learning happens. Mistakes on test pieces can lead to perfection on your final project.

The Role of Brackets: Enhancing Structure and Support in Furniture

Brackets play a crucial role in furniture design. They enhance structure and support, allowing pieces to withstand weight and stress. In bookcases, metal brackets can secure shelves firmly, preventing sagging. Wooden brackets add a classic look while providing sturdy support.

Consider dining tables as another example. Here, angle brackets can reinforce joints. They connect the tabletop to the legs, offering stability. However, it's essential to choose the right size. If the brackets are too small, they may fail under pressure.

Not every furniture piece needs brackets; some designs are sleek without visible supports. But for others, they are indispensable. The balance between aesthetics and functionality is often challenging. A well-placed bracket can make a difference, both in safety and style. Reflecting on this, some may wonder if their current furnishings are robust enough for daily use. Making adjustments can enhance longevity and usability.

Innovative Fastening Techniques: Beyond Traditional Methods

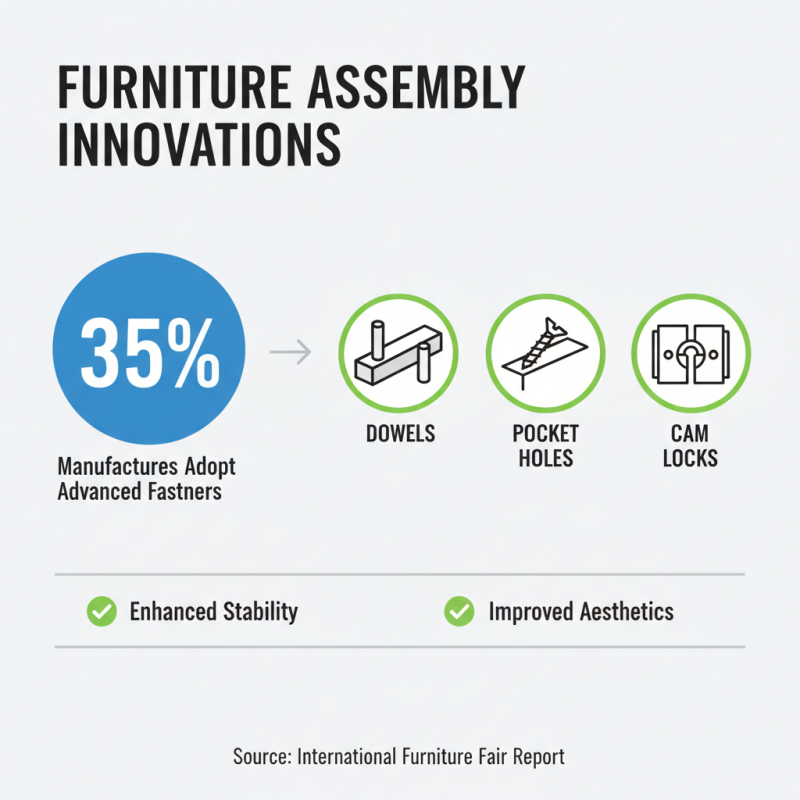

In the realm of furniture assembly, traditional fasteners like screws and nails have long dominated. Yet, innovative fastening techniques are transforming the industry. According to a report by the International Furniture Fair, 35% of manufacturers have started adopting advanced fastening solutions. These include dowels, pocket holes, and cam locks, which offer enhanced stability and aesthetics.

Fastening methods like interlocking joints are gaining traction too. These joints minimize the need for visible hardware, resulting in a sleeker appearance. Additionally, studies show that 60% of consumers prioritize design over functionality in furniture. This shift is pushing companies to embrace creative solutions that blend form and function seamlessly. However, these innovations come with challenges. Not every new method proves effective in various materials, leading to trial and error in production.

Alternative fastening techniques also raise sustainability concerns. Some methods require specialized tools or materials that may not be widely available. It’s a delicate balance between modern techniques and practical applications. The promise of innovation is enticing, but the realization of that promise requires thorough testing and adaptation. As the industry evolves, manufacturers must continually reflect on their practices to ensure they meet both consumer expectations and environmental standards.

Related Posts

-

10 Best Furniture Fasteners for Durable and Reliable Assembly

-

How to Choose the Best High Quality Carriage Bolt for Your Project

-

Why You Need High Quality Carriage Bolts for Your DIY Projects

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

What is a Stainless Wood Screw and How to Choose the Right One?