How to Use Torx Screws for Optimal Performance and Durability?

In the realm of fastening technology, Torx screws have garnered considerable attention for their unique design and effectiveness. Considered an invaluable tool by industry experts, Torx screws offer enhanced grip and reduced slipping compared to traditional screw types. James Thompson, a well-respected engineer in fastener technology, once remarked, "Torx screws provide a level of reliability that is hard to match." This statement encapsulates the essence of why proper usage of Torx screws is crucial.

Employing Torx screws can significantly impact the performance and durability of your project. Their star-shaped design allows for greater torque transfer without damaging the screw head. However, many users overlook essential techniques to maximize their benefits. For instance, using the correct driver size is vital to avoid stripping. Improper handling can lead to frustrating setbacks.

Understanding the nuances of Torx screws is essential for achieving optimal results. The choice of materials and coatings also plays a significant role. Not all environments are suitable for every type of Torx screw. Reflecting on personal experiences can illuminate these challenges. Ensuring the right application can enhance not just performance, but longevity as well.

Understanding Torx Screws: Design and Benefits

Understanding Torx screws reveals their unique design and distinct benefits. Unlike traditional screws, Torx screws feature a star-shaped pattern. This design allows for better torque transfer, minimizing the risk of stripping. Data from industry reports shows that using Torx screws can reduce stripping incidents by up to 75%. This advantage is particularly significant in high-tension applications.

Another key benefit of Torx screws is their ability to resist cam-out. Cam-out occurs when the driver slips out of the screw head, which can lead to inefficiency. Research indicates that users often experience less fatigue when using Torx screws due to their improved engagement. Many professionals appreciate the effortless turning they provide. However, one must be cautious; improper sizing of the driver can still lead to issues.

Industries often overlook the importance of screw choice in assembly lines. While Torx screws are effective, they also require compatible tools. This can lead to confusion on site if different types of screws are present. Though Torx screws are durable, they need careful handling. Regular inspections can help maintain their reliability.

Selecting the Right Torx Screw Size for Your Project

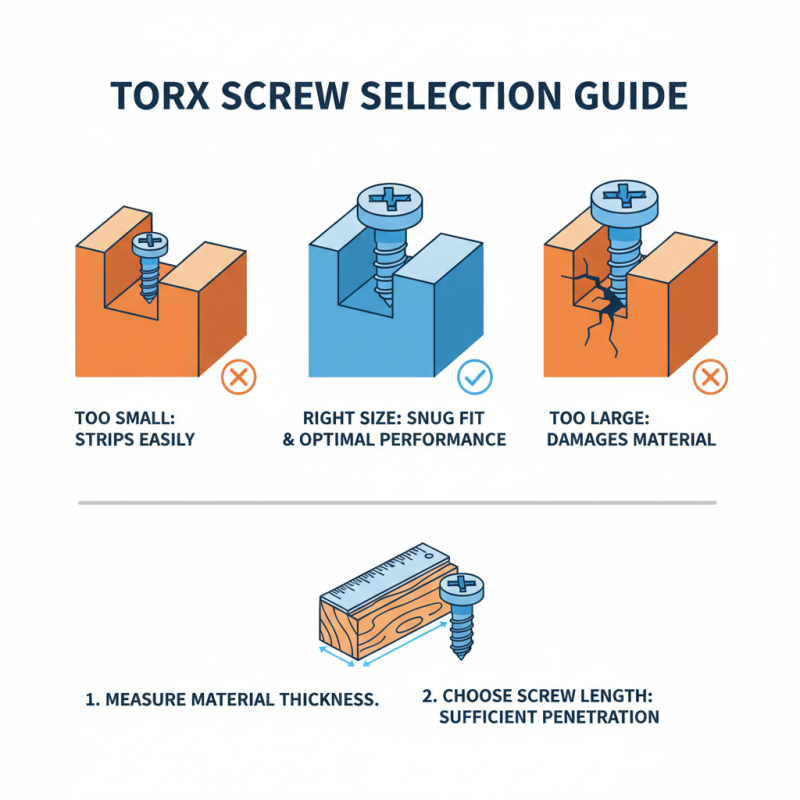

When working on a project, selecting the right Torx screw size is crucial. A proper size ensures a snug fit and optimal performance. If the screw is too small, it may strip easily. If it's too large, it could damage the material. Start by measuring the thickness of the material you're using. Aim for a screw length that penetrates sufficiently without protruding.

Here are a few tips for choosing the right size. Use a gauge to measure the diameter of the screw. This will help you match it accurately to your project needs. Always refer to technical specifications for guidance. Sometimes, there may be a need to test fit screws before making a final decision.

Don't overlook the importance of the screw head type. Torx screws come in various sizes and shapes. A wrong head type may render your tool useless. Keep a few different sizes on hand. This can reduce frustration during your build. Also, consider the depth of the screw. The deeper it goes, the more secure it will be. Make sure to assess this before you start.

Tools Required for Installing Torx Screws Effectively

When installing Torx screws, the right tools are essential. A high-quality Torx screwdriver is a must. These screwdrivers ensure a secure fit, reducing the likelihood of stripping the screw head. According to industry reports, using the correct screwdriver can increase torque application by up to 30%. This means better tightening power, and ultimately, improved durability of the installation.

In addition to the screwdriver, a torque wrench is also highly recommended. A torque wrench helps to apply the right amount of force. Over-tightening can lead to damage, while under-tightening can cause failure. The balance is vital. Studies show that up to 15% of installation issues arise from torque miscalculations.

Lastly, using a magnetic bit holder can enhance the installation process. It helps keep the screws stable, especially in hard-to-reach areas. Maintaining focus on tool quality and proper technique is critical. Small mistakes can lead to larger problems down the road. It’s worth examining your current tools and updating them when necessary.

Techniques for Achieving Optimal Performance with Torx Screws

Torx screws are increasingly preferred for applications where durability is key. Their star-shaped design allows for better torque transfer than traditional screws. This leads to improved performance in a range of settings, from automotive to construction.

To achieve optimal performance with Torx screws, it is essential to use the right bit size. Using a mismatched bit can cause stripping, resulting in inefficiencies. A report by the Fastener Industry Association indicates that improper screw usage can decrease fastening integrity by up to 30%. Ensure your tools match the screw precisely for the best results.

Tips: Always inspect screw and bit for wear before use. Replace them when you notice signs of fatigue. Additionally, consider the material of both the screw and the surface. Misalignment can weaken fasteners over time. Regular checks can save you from costly repairs and replacements in the long run. Pay attention to details; even small mistakes can lead to significant issues in performance.

Performance Metrics of Torx Screws vs. Traditional Screws

This bar chart illustrates the performance metrics of Torx screws compared to traditional screws. Metrics include Torque Resistance, Stripping Resistance, Durability, Ease of Installation, and Cost Efficiency, showcasing the advantages of using Torx screws in various applications.

Maintenance Tips for Enhancing Durability of Torx Screw Fastenings

Maintaining Torx screw fastenings is essential for optimal performance. Regular inspection is crucial. Check for signs of wear or corrosion. Rust can weaken screws, making them less reliable. If you notice any damage, replace them promptly. This simple step could prevent larger issues.

Using the correct tools is also important. A proper Torx driver ensures a snug fit. A loose fit can strip the screw head. This makes future removal difficult. Invest in a quality tool set. Cheap alternatives can lead to problems down the line.

Environmental factors play a role, too. Exposure to moisture can cause damage. Consider applying a protective coating. This adds an extra layer of durability. Regular cleaning is necessary as well. Dirt and debris can accumulate over time. This can affect not just the screws, but the entire assembly. Take a moment to assess your fastenings regularly. Reflection on your maintenance routine can lead to better outcomes.

How to Use Torx Screws for Optimal Performance and Durability? - Maintenance Tips for Enhancing Durability of Torx Screw Fastenings

| Aspect | Details |

|---|---|

| Screw Type | Torx (also known as star) screws are designed for optimal grip and torque. |

| Material | Commonly made from carbon steel or stainless steel for durability. |

| Sizes | Available in various sizes ranging from T1 to T100, with T10 to T30 being the most common. |

| Torque Rating | Higher torque ratings compared to Phillips and slotted screws, minimizing stripping. |

| Maintenance Tip | Ensure the use of the correct driver size to prevent damage to the screw head. |

| Application Areas | Commonly used in automotive, electronics, and furniture industries. |

| Best Practices | Avoid over-tightening; use appropriate lubricant for smoother operation. |

Related Posts

-

How to Use Torx Screws for Effective and Secure Fastening Solutions

-

2026 Best Truss Head Carriage Bolt Guide for Your Projects?

-

Top 2025 Furniture Screw Types: Which One is Right for Your Project?

-

Top 10 Stainless Carriage Bolt Options for Your Next Project

-

Best High Tensile Carriage Bolt Applications and Benefits?

-

How to Choose the Right Stainless Bolt for Your Project?