How to Use Torx Screws for Effective and Secure Fastening Solutions

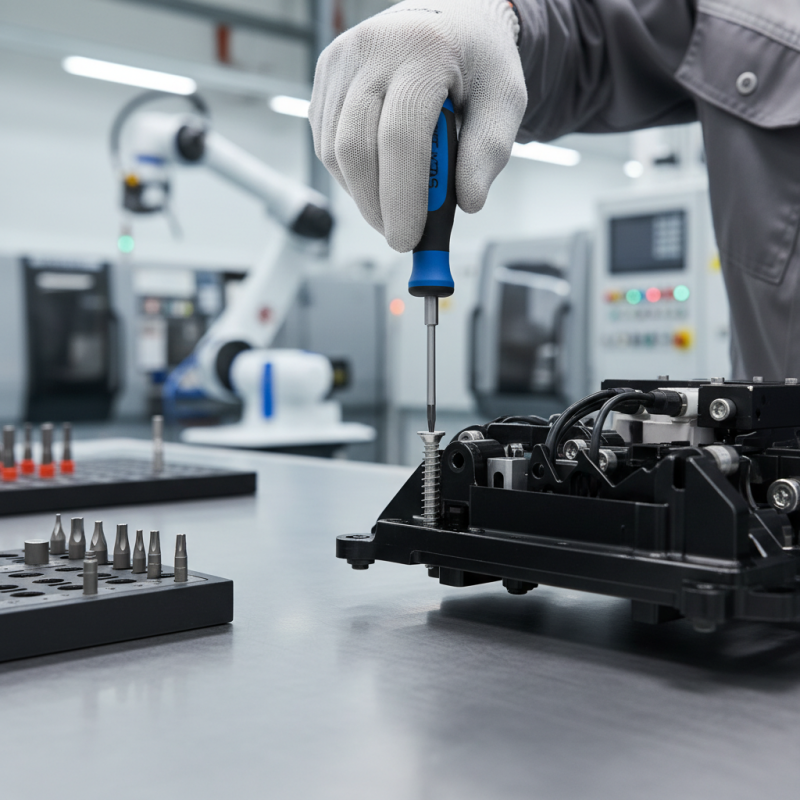

In the realm of fastening solutions, the Torx Screw has emerged as a vital component for ensuring robust and secure assemblies. Unlike traditional screws, the unique design of the Torx head allows for greater torque transfer and minimizes the risk of stripping, making it a preferred choice among engineers and manufacturers alike. As Dr. Emily Carter, a recognized expert in fastening technologies, states, “The Torx Screw offers unparalleled strength and reliability, transforming how we approach fastening in various applications.”

This innovative fastening solution is particularly advantageous in industries where precision and security are paramount. The six-point star shape of the Torx Screw not only enhances grip but also allows for smoother operation during installation and removal. With the increasing demand for more effective and secure fastening solutions, understanding how to properly use Torx Screws is essential for professionals in manufacturing, automotive, and construction sectors.

This article delves into the practical aspects of utilizing Torx Screws, exploring their benefits, installation techniques, and best practices that ensure secure fastening. By harnessing the capabilities of Torx Screws, industries can achieve superior performance, reduce downtime, and enhance the overall integrity of their projects.

Understanding Torx Screws: Design and Benefits

Torx screws, known for their distinctive star-shaped design, have gained popularity in various industries due to their superior grip and torque transmission capabilities. This design mitigates the risk of stripping, a common issue with traditional screw heads, allowing for a more reliable fastening solution. According to a study by the Fastener Quality Act, the use of Torx screws can increase the efficiency of assembly processes by up to 30% when compared to Phillips and slotted screws, particularly in high-stress applications that require secure fastening.

The unique design of Torx screws not only enhances performance but also offers several distinct benefits. Their resistance to cam-out — the tendency of the screwdriver to slip out of the screw head during tightening — makes them ideal for automated assembly lines. Additionally, a report from the International Fastener Industry Association indicates that the prevalence of Torx screws contributes significantly to reducing maintenance costs, as their secure fastening reduces the likelihood of loosening over time. Given these advantages, industries ranging from automotive to electronics increasingly opt for Torx screws to meet stringent performance standards and ensure product reliability.

Choosing the Right Torx Screw for Your Project

When selecting the right Torx screw for your project, understanding the various types and sizes available is crucial. Torx screws, known for their star-shaped drive, provide superior grip and reduce the likelihood of stripping compared to traditional screws. Begin by assessing the materials you will be fastening together. For wood applications, a coarse-thread Torx screw may be ideal, while finer-thread screws work better with metal or plastic.

Tips: Always carry a range of Torx screw sizes in your toolkit to ensure you have the right fit for any job. Additionally, consider the length of the screw; a longer screw may be necessary for thicker materials, while a shorter screw may suffice for thin boards.

Choosing the right material is also significant. Stainless steel Torx screws offer corrosion resistance, making them perfect for outdoor or high-moisture environments. For interior projects, you might opt for zinc-coated screws, as they provide good durability and are often more cost-effective. With proper selection, Torx screws can dramatically enhance the structural integrity of your projects while providing secure fastening solutions.

Usage of Torx Screws in Various Applications

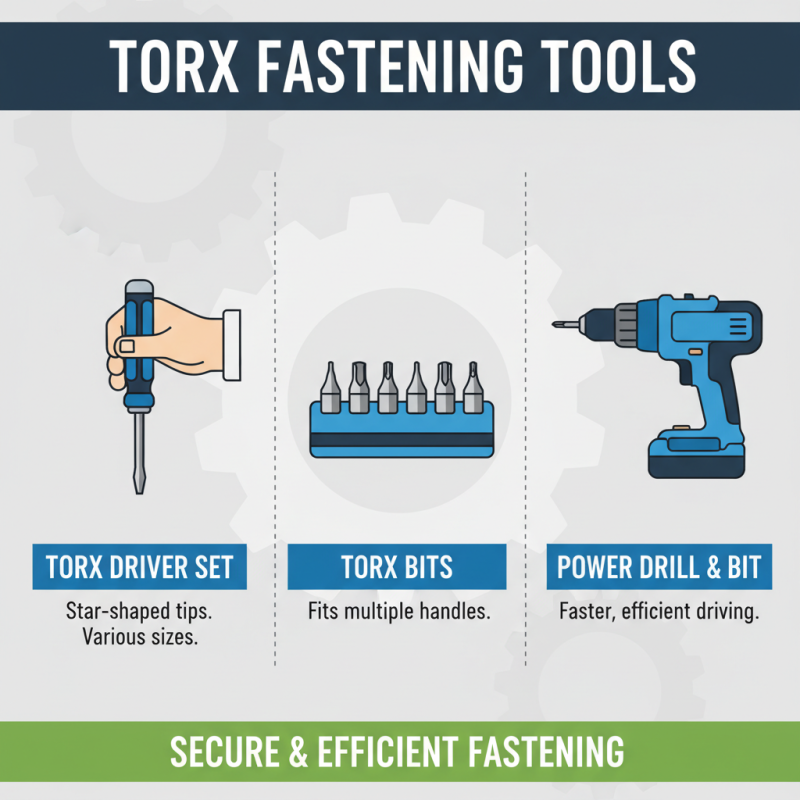

Tools Required for Working with Torx Screws

When working with Torx screws, having the right tools is crucial for achieving effective and secure fastening. The primary tool you’ll need is a Torx driver or bit, which is specifically designed to fit the unique star-shaped pattern of the screw head. These drivers come in various sizes, so it’s important to have a complete set to accommodate different screw sizes. Additionally, a power drill with a Torx bit can make the job faster and more efficient, especially for larger projects.

Tip: Always match the size of your Torx driver to the screw size to prevent damage. An incorrect driver can strip the screw head, making removal and replacement difficult.

Other essential tools include a screwdriver with a secure grip for manual adjustments, as well as a torque wrench for ensuring screws are tightened to the correct specifications without overtightening. Using a magnetic pick-up tool can also be beneficial for retrieving screws from tight or hard-to-reach places.

Tip: Keep your tools organized and in good condition to ensure smooth operation. Regularly check for wear and replace any damaged tools to maintain effective fastening solutions.

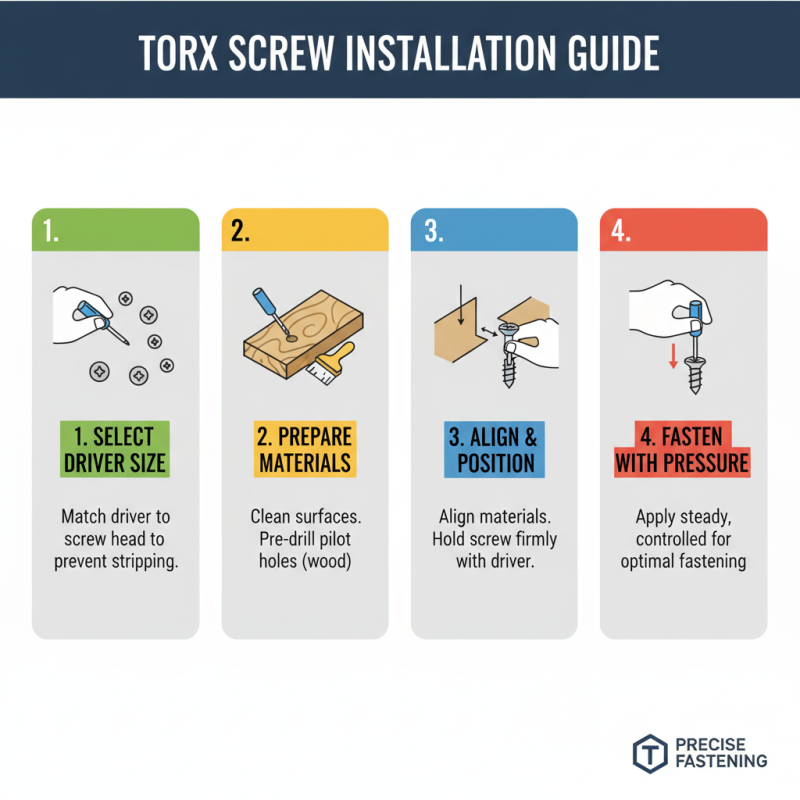

Step-by-Step Guide to Installing Torx Screws

Installing Torx screws requires a precise approach to ensure optimal fastening. Start by selecting the appropriate size Torx driver for your screws, as using the wrong size can strip the screw head. Before beginning installation, prepare your materials and tools to avoid interruptions. Clean the surfaces being fastened and, if necessary, pre-drill pilot holes to prevent wood from splitting. Align the materials and handle the Torx screw with the driver firmly, applying steady pressure to maintain control.

Tips: When working with Torx screws, consider using a magnetic tip on your driver to make handling easier, especially in tight spaces. Additionally, avoid over-tightening, as this can lead to damage or deformity of the screw or material being fastened. If you find that installation is difficult, check for debris or misalignment, and adjust as necessary before proceeding.

Once you ensure everything is in order, insert the Torx screw and begin turning slowly. You should feel the screw engage with the material. This unique head design offers superior grip, reducing the chance of slipping, which is common with other screw types. Keep applying consistent pressure and check your progress regularly to achieve a secure and effective fastening.

Maintenance Tips for Longevity of Torx Screw Connections

To ensure the longevity of Torx screw connections, regular maintenance practices are essential. Start by inspecting the screws periodically for any signs of wear or damage. This includes checking for stripped heads and rust, which can compromise the integrity of the fastening. If any wear is detected, it is crucial to replace the affected screws immediately to prevent potential failures in the assembly.

Another vital maintenance tip is to keep the screw connections clean. Accumulation of dirt, dust, and debris can lead to improper seating and may cause screws to loosen over time. Use a soft brush or cloth to gently clean the area around the screws and ensure a snug fit during reassembly. Additionally, consider applying a light lubricant to the threads to facilitate smoother engagement and enhance protection against corrosion.

Lastly, always use the correct Torx tool size to avoid stripping the screw heads. Employing the right tool not only preserves the fastener but also ensures safer and more efficient installation and removal. By following these maintenance tips, you can maximize the lifespan of your Torx screw connections and maintain their effectiveness in providing secure fastening solutions.

How to Use Torx Screws for Effective and Secure Fastening Solutions - Maintenance Tips for Longevity of Torx Screw Connections

| Screw Type | Drive Size | Recommended Tool | Usage Applications | Maintenance Tips |

|---|---|---|---|---|

| Torx T10 | T10 | Torx Driver | Electronics, Small Appliances | Ensure drivers fit snugly to avoid stripping |

| Torx T20 | T20 | Torx Driver | Automotive, Furniture Assembly | Regularly check for torque to maintain tightness |

| Torx T25 | T25 | Torx Driver | Heavy Machinery, Construction | Clean regularly to prevent rust and build-up |

| Torx T30 | T30 | Torx Driver | Furniture, Industrial Applications | Store in dry conditions to avoid moisture damage |

| Torx T40 | T40 | Torx Driver | Machinery, Automotive Parts | Inspect screws periodically for wear and tear |